Centralized LED Lighting Drivers Set the Standard for Cost Savings

Veröffentlicht Oktober 23, 2024 von Chris Jones

Reduce Expenses with Centralized LED Lighting Solutions

Key Takeaways:

- Applications: The new LED lighting approach benefits horticulture, parking garages, warehouses, and industrial facilities by enhancing productivity and reducing costs.

- Conventional Challenges:

- Heat Emission: Individual LED drivers generate heat, increasing cooling costs.

- Efficiency Loss: Significant energy loss due to heat dissipation.

- Complexity and Cost: Each driver requires its own control system and cabling, leading to higher installation costs and potential reliability issues.

- Centralized, Remote Driver Benefits:

- Reduced Complexity: One centralized unit replaces multiple drivers, simplifying installation and reducing costs.

- Heat Management: Centralized drivers generate less heat, improving energy efficiency and reducing cooling needs.

- Environmental Stability: Helps maintain stable temperature, humidity, and CO2 levels in sensitive environments like greenhouses.

- LumaDrive™ System:

- Turnkey Solutions: Pre-wired power solutions for easy installation and maintenance.

- Configurations: Available in various power configurations to suit different needs.

- Environmental Protection: Can be placed outside sensitive areas, reducing the need for costly IP-rated solutions.

- Compatibility: Works with any LED lighting system controller, PLC, or industrial computer.

- Cost Savings:

- Capital Costs: Up to 35% savings on initial costs compared to individual LED driver systems.

- Operational Costs: Approximately 20% annual savings on energy and maintenance.

- This centralized approach simplifies installation, reduces costs, and improves efficiency and reliability in various industrial and horticultural applications.

A new approach to LED lighting systems offers tangible benefits to the bottom line across a range of applications. This includes horticulture operations, with industrial-scale greenhouses enabling larger and more productive harvests, as well as underground or multi-story parking garages, warehouses and other industrial facilities.

The conventional approach to LED lighting requires an individual LED driver power supply on each light fixture. Each driver emits heat that requires mitigation via air conditioning to re-cool the environment room, such as a greenhouse or warehouse. This increases the cost of the initial infrastructure and ongoing energy requirements.

Putting this in context, an LED driver running 1,000 W lights typically operates at 95% efficiency, losing 50 W of heat per driver. A 1,500 LED driver system loses 75,000 W, or a little over 255,000 BTUs per hour that requires dissipation.

This isn’t the only drawback of the conventional approach. Each driver also requires its own control system and cabling infrastructure, adding significant complexity, and therefore cost, to the installation. This approach also has many potential points of failure, which affects reliability. Furthermore, driver failures often necessitate ceiling-level repairs, which are costly, time consuming, and pose potential risk to maintenance workers.

The benefits of a centralized, remote driver approach

Powering all LED fixtures with a centralized, remote power system immediately reduces complexity and cost. One unit replaces the numerous drivers required in a conventional approach. In addition, locating the driver remotely protects it from damp or particulate-filled environments and eliminates the need for ingress protection (IP). In situations where it’s necessary to locate the driver within the environment, only one unit requires specialized protection versus many separate drivers that each require IP.

A centralized, remote power supply also reduces generated heat and overall energy usage. While the electrical efficiency of individual and centralized drivers is roughly equivalent, reduction of generated heat makes the centralized approach more cost effective. Locating the driver outside the environment allows heat to exhaust outdoors to prevent product or crop damage. As winter comes and temperatures drop, this heat can be redirected back to reduce heating bills.

This approach also helps to ensure greenhouses and warehouses have fewer temperature fluctuations and more stable humidity and CO2 levels.

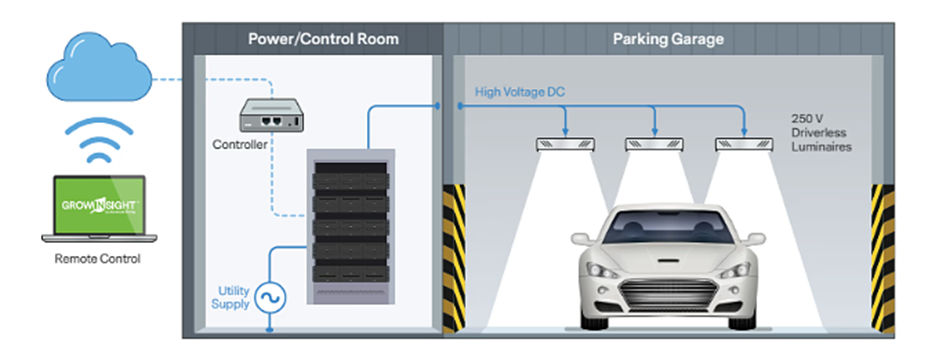

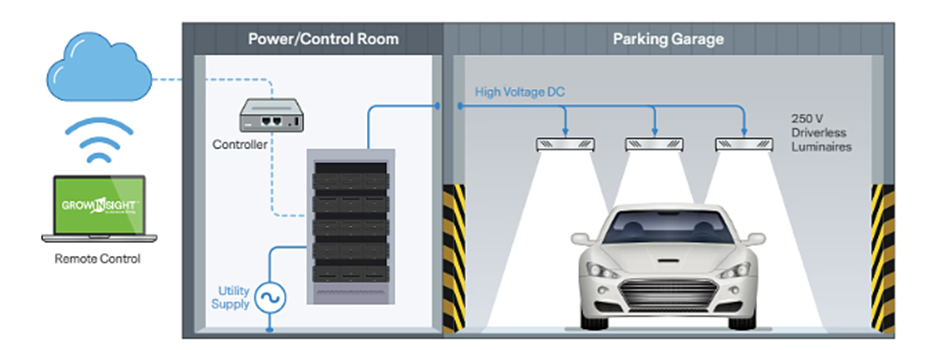

Figure 1: A centralized LED driver applied to commercial and horticultural use cases

The LumaDrive™ system

Advanced Energy’s LumaDrive power supplies for industrial LED systems are turnkey solutions designed to take the advantages of centralized power to the next level, with pre-wired power solutions that simplify installation and maintenance.

Designed for challenging environments such as horticulture, warehouses, factories and parking garages, the LumaDrive family offers configurations of 144 kW, 72 kW, 36 kW and 24 kW by combining up to 36 units of the 4 kW power modules in a pre-wired cabinet.

The LumaDrive’s centralized power system can be placed outside of areas where there are environmental concerns (such as greenhouses and other horticultural applications), which removes the need to have IP-rated solutions that add cost and complexity. Additionally, since the control can also be centrally located, extra wiring and complexity of multiple control locations are eliminated, which is also beneficial in applications such as parking garages and warehouses.

LumaDrive uses Advanced Energy’s LCM4000HV series and associated LCM12K mounting shelf that have been designed specifically to provide a centralized current source for medium to large scale LED lighting and horticulture applications.

Finally, LumaDrive is compatible with any LED lighting system controller, PLC or industrial computer, eliminating the need to control wiring to each Luminaire.

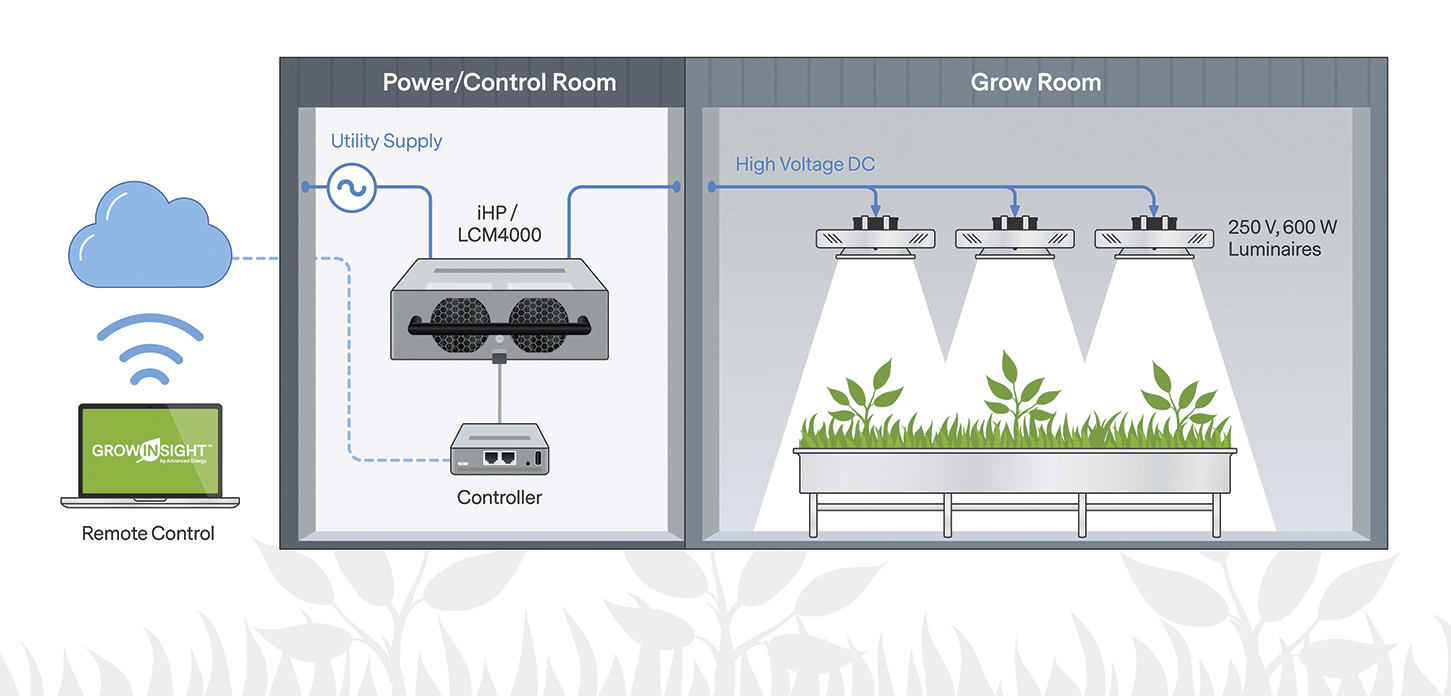

Figure 2: The LumaDrive Systems for high efficiency large-scale industrial and horticultural LED lighting

Savings from a centralized approach

Real world data from Advanced Energy customers suggests a centralized or remote approach implemented with LED drivers for horticultural or industrial applications can deliver significant savings.

These savings are specific to each application and the scale of each deployment. However, data has shown savings on initial capital costs for AE customers can be up to 35% compared with systems using individual LED drivers. Additionally, annual operational costs are also reduced, with data from customers showing approximately 20% in savings.

For more information on Advanced Energy’s LumaDrive systems, visit here: LumaDrive™ Systems | High-Efficiency, Pre-wired Remote Driver Systems for Lighting | Advanced Energy.

Chris Jones

Advanced Energy

Chris Jones is Advanced Energy's Director of Technical Product Marketing for System Power

Mehr Beiträge von Chris Jones

durchsuchen

Kategorien A-Z

Tragen Sie sich in unsere Mailingliste ein

Abonnieren

Neueste Beiträge

View on X