How SCR power controllers improve industrial electric furnace economics

Veröffentlicht November 07, 2017 von Advanced Energy Editor

It goes without saying that for efficient industrial furnace operations, SCR based power control modules (PCMs) need to possess a wide range of integrated features that enable precision temperature control, process reliability and, ultimately, end product quality.

Integral to these operations are the thermal processing control system (such as a Rockwell Automation® Programmable Automation Controller), temperature measurement loops for control and shut-off – these being typically either thermocouple based, or for more harsh environments, Pyrometers – and a power control architecture that regulates the energy input to the furnace heaters via SCR power controllers.

When operating the furnace, the process temperature is measured and compared to a desired set-point, this being sent as an input to a PID loop that resides in either the Programmable Automation Controller (PAC) or a temperature controller, depending on the control scheme. This corrective trim signal (4-20mA, 0-10V, Ethernet command, etc.) is then sent to the SCR power controller that modifies the energy input to the heating elements to reach the desired set point.

When it comes to electrical wiring best practices, analog control signal cabling, such as required by thermocouples, should be kept as short as possible in length and as far away from furnace power cabling as practical - all in order to minimize electrical interference. The installation sensitivity to interference typically diminishes when digital communication protocols are used instead of analog signals.

A fully integrated control architecture?

The challenge that many furnace operations face is that even though their control systems conform to – and implement – installation best practices, the end result often comprises of a group of disparate components flung together instead of a highly synchronized network of architectural elements that natively integrate into the control system’s communication and configuration capabilities.

This is a challenge that many furnace installations suffer from.

In contrast to this, if the control components are designed to natively connect to the PAC, they become extensions of the PAC architecture itself – with all the benefits that come with it. An example of how the challenges of combining disparate components can be overcome is through the architectural approach implemented by the Logix PAC from Rockwell Automation combined with Advanced Energy’s Thyro power controllers and Onyx pyrometers. With native Add-On-Profiles (AOPs) added to the Rockwell Automation Studio 5000 Logix Designer environment, the thyro power controllers and Onyx pyrometer temperature measurements are tightly integrated architectural elements of an overall control system.

The benefits of the architectural power control module

Architecturally integrated SCR power controllers have the potential to generate multiple benefits to the whole furnace operation, whether it be through greater heater lifetime, optimized power consumption or improved product uniformity.

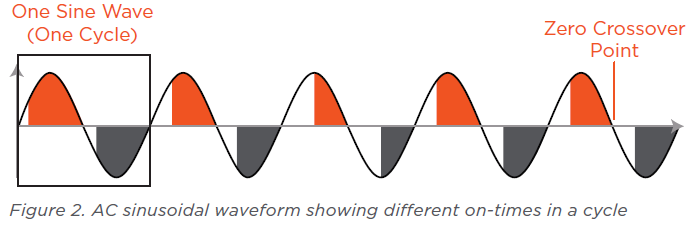

At 99.5 percent efficiency, SCR power controllers provide distinct advantages over alternative technologies through their multiple modes of operation such as Zero-Crossing and Phase-Angle Firing. Application of these features can minimize parasitic harmonics that reduce transformer lifetimes as well as the capability to balance heater usage and minimize the number of their on-off thermal cycles. Whilst end-product quality is the ultimate indicator of success, this cannot be considered apart from the need to operate a furnace economically. Power consumption is always a major concern for furnace operators, especially when only dirty power, with power factors of less than one, is available. These types of inefficiency often cause significant penalties to the user when it comes to on-going utility spend. SCR technology can improve the power factor efficiency available to the furnace and thus reduce utility costs.

.jpg?resizemode=force&maxsidesize=884)

.png?resizemode=force&maxsidesize=884)