Powering Sustainable Glass Production

Veröffentlicht Oktober 01, 2024 von Advanced Energy Editor

Key Takeaways

Glass’s Modern Importance: Glass remains crucial in modern life, especially in construction, solar energy, and mobile devices.

Diverse Applications: Glass is used in various forms, including flat, solar, utility, technical, and thin sheet glass.

Energy-Intensive Manufacturing: Glass production requires significant heat and energy, traditionally relying on fossil fuels.

Shift to Electrical Power: Due to environmental concerns, glass manufacturing is moving towards electrical power.

Efficiency of SCR Power Controllers: Silicon-controlled rectifier (SCR) power controllers, like Advanced Energy’s Thyro-PX, offer high efficiency (up to 99.5%) and precise control, making them ideal for glass production.

Advanced Features: Advanced Energy’s Thyro-PX controllers support multiple applications with modular design, high accuracy, and advanced features, ensuring stability and reducing energy losses.

Enhanced Power Management: These controllers facilitate mains load optimization, reducing the impact on the grid and ensuring even power distribution.

Future Innovations: Advanced Energy continues to innovate with new Thyro-PX units offering higher voltage and current capabilities, minimizing losses and supporting higher power applications.

Far from being an ‘old’ technology, glass remains at the center of modern life and is expected to continue its importance for a long time.

It is increasingly used in construction applications and is also essential to solar energy components, such as photovoltaic panels, that will be key to a sustainable future. Alongside this, billions of mobile devices such as tablets and smartphones have been shipped. Every single one of these devices relies on glass for the screen, which is the primary human-machine interface (HMI).

Glass is available in many forms including flat or solar glass made by a ‘float’ process, utility glass for containers, technical glass for lighting and thin sheet glass for modern handheld devices.

While each of the manufacturing processes are different, they all share the need for heat input to soften and melt the glass. The temperatures are high, and the process can be long, with some manufacturers1 citing 1100°C for up to 50 hours, and temperatures up to 1500°C within the process.

Clearly, glass manufacturing requires a significant amount of energy. For more than a century, glass manufacturers relied on fossil fuels such as gas, and in some cases oil, to meet this need. However, the environmental impact of these resources has led to a shift towards electrical power.

The massive electrical heaters used in glass manufacturing require a power source that is accurate, precise and efficient to produce specific material effects or properties. This is where silicon-controlled rectifier (SCR) power controllers come in. They offer up to 99.5% efficiency in power delivery, making them ideal for high-power applications.

Compared to alternative devices, such as IGBT-based controllers, SCR power controllers provide much greater efficiency. This low-loss performance is crucial in all high-power applications.

Advanced Energy’s Thyro-PX® digital thyristor SCR power controllers are a modular solution for applications such as glass manufacturing that require heating. The single-, dual- and three-phase solutions are highly accurate (±0.5% voltage or current, ±1.0% power) ensuring stability and repeatability within the manufacturing process.

Glass’s Modern Importance: Glass remains crucial in modern life, especially in construction, solar energy, and mobile devices.

Diverse Applications: Glass is used in various forms, including flat, solar, utility, technical, and thin sheet glass.

Energy-Intensive Manufacturing: Glass production requires significant heat and energy, traditionally relying on fossil fuels.

Shift to Electrical Power: Due to environmental concerns, glass manufacturing is moving towards electrical power.

Efficiency of SCR Power Controllers: Silicon-controlled rectifier (SCR) power controllers, like Advanced Energy’s Thyro-PX, offer high efficiency (up to 99.5%) and precise control, making them ideal for glass production.

Advanced Features: Advanced Energy’s Thyro-PX controllers support multiple applications with modular design, high accuracy, and advanced features, ensuring stability and reducing energy losses.

Enhanced Power Management: These controllers facilitate mains load optimization, reducing the impact on the grid and ensuring even power distribution.

Future Innovations: Advanced Energy continues to innovate with new Thyro-PX units offering higher voltage and current capabilities, minimizing losses and supporting higher power applications.

Far from being an ‘old’ technology, glass remains at the center of modern life and is expected to continue its importance for a long time.

It is increasingly used in construction applications and is also essential to solar energy components, such as photovoltaic panels, that will be key to a sustainable future. Alongside this, billions of mobile devices such as tablets and smartphones have been shipped. Every single one of these devices relies on glass for the screen, which is the primary human-machine interface (HMI).

Glass is available in many forms including flat or solar glass made by a ‘float’ process, utility glass for containers, technical glass for lighting and thin sheet glass for modern handheld devices.

While each of the manufacturing processes are different, they all share the need for heat input to soften and melt the glass. The temperatures are high, and the process can be long, with some manufacturers1 citing 1100°C for up to 50 hours, and temperatures up to 1500°C within the process.

Clearly, glass manufacturing requires a significant amount of energy. For more than a century, glass manufacturers relied on fossil fuels such as gas, and in some cases oil, to meet this need. However, the environmental impact of these resources has led to a shift towards electrical power.

The massive electrical heaters used in glass manufacturing require a power source that is accurate, precise and efficient to produce specific material effects or properties. This is where silicon-controlled rectifier (SCR) power controllers come in. They offer up to 99.5% efficiency in power delivery, making them ideal for high-power applications.

Compared to alternative devices, such as IGBT-based controllers, SCR power controllers provide much greater efficiency. This low-loss performance is crucial in all high-power applications.

Advanced Energy’s Thyro-PX® digital thyristor SCR power controllers are a modular solution for applications such as glass manufacturing that require heating. The single-, dual- and three-phase solutions are highly accurate (±0.5% voltage or current, ±1.0% power) ensuring stability and repeatability within the manufacturing process.

Fig 1. Thyro-PX

Fig 1. Thyro-PX

AE’s Thyro-PX controllers are ideal for efficient power delivery in glass manufacturing

Thyro-PX controllers operate with line voltages up to 1000 V and can deliver currents as high as 5000 A. The controllers incorporate a multi-zone capability that permits independent control of multiple single-phase loads from a single controller.

An (optional) inbuilt Thyro-Touch 2.8” display enables intuitive operation of the unit and includes an integrated process data recorder for long-term data recording of up to six process parameters as well as status messages. For integration into a wider control system, an Anybus® Fieldbus Card allows use of many popular protocols including Ethernet / IP, EtherCAT, PROFIBUS, PROFINET, Modbus TCP/IP and DeviceNET.

When electrical power is used in glass manufacturing process applications, the power levels can be significant. For example, in roof heating the load per element is around 3.75 kW, which leads to >100 kW for 27 elements in a parallel configuration.

To address the thermal inertia, the controllers operate in Full Wave (TAKT) mode, which reduces wattless power and eliminates harmonic components. It also simplifies synchronization.

TAKT operation also facilitates mains load optimization, which reduces the impact of multiple power controllers being simultaneously attached to the grid. Advanced Energy’s digital and dynamic mains load operation considerably reduces peak loads on the mains, ensuring even distribution. It also considers setpoint and load changes.

With power levels increasing, Advanced Energy recently announced a new Thyro-PX unit with a 1000 V output voltage. This multi-phase air-cooled unit offers up to 900 A and reduces the current supplied to the heater, for the same power level.

The reduced current minimizes losses in cables and busbars due to I2R, allowing for thinner and lighter installations – as well as saving costs.

Stacking for Higher Current Applications

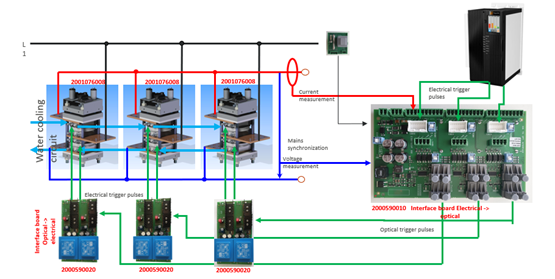

Some applications will require even higher current ranges. The Thyro-PX platform can accommodate these higher levels through its ability to operate thyristors in a parallel, water-cooled stack configuration.

Thyro-PX controllers operate with line voltages up to 1000 V and can deliver currents as high as 5000 A. The controllers incorporate a multi-zone capability that permits independent control of multiple single-phase loads from a single controller.

An (optional) inbuilt Thyro-Touch 2.8” display enables intuitive operation of the unit and includes an integrated process data recorder for long-term data recording of up to six process parameters as well as status messages. For integration into a wider control system, an Anybus® Fieldbus Card allows use of many popular protocols including Ethernet / IP, EtherCAT, PROFIBUS, PROFINET, Modbus TCP/IP and DeviceNET.

When electrical power is used in glass manufacturing process applications, the power levels can be significant. For example, in roof heating the load per element is around 3.75 kW, which leads to >100 kW for 27 elements in a parallel configuration.

To address the thermal inertia, the controllers operate in Full Wave (TAKT) mode, which reduces wattless power and eliminates harmonic components. It also simplifies synchronization.

TAKT operation also facilitates mains load optimization, which reduces the impact of multiple power controllers being simultaneously attached to the grid. Advanced Energy’s digital and dynamic mains load operation considerably reduces peak loads on the mains, ensuring even distribution. It also considers setpoint and load changes.

With power levels increasing, Advanced Energy recently announced a new Thyro-PX unit with a 1000 V output voltage. This multi-phase air-cooled unit offers up to 900 A and reduces the current supplied to the heater, for the same power level.

The reduced current minimizes losses in cables and busbars due to I2R, allowing for thinner and lighter installations – as well as saving costs.

Stacking for Higher Current Applications

Some applications will require even higher current ranges. The Thyro-PX platform can accommodate these higher levels through its ability to operate thyristors in a parallel, water-cooled stack configuration.

Fig 2. The above figure shows configuration example that separates the control section from the power section to use the Thyro-PX in higher voltage applications. SCR system components for stacked configuration

Fig 2. The above figure shows configuration example that separates the control section from the power section to use the Thyro-PX in higher voltage applications. SCR system components for stacked configurationThese stacks, which comprise multiple thyristor disc cells of different sizes based on application, support DC and both single-phase and three-phase AC designs and take full advantage of the existing Thyro-PX card architecture for precise and accurate control and advanced communications. With the advantage of separating the control section from the power section via fiber optic Thyristor signaling, EMC problems can be avoided. The Thyro-PX Modular allows high currents up to 12 kA at 690 V.

Find out more about Thyro-PX here and how it is used in glass applications.

Notes

1 - https://www.pilkington.com/en/global/knowledge-base/glass-technology/the-float-process/the-float-process-step-by-step#

Advanced Energy Editor

Advanced Energy

durchsuchen

Kategorien A-Z

Tragen Sie sich in unsere Mailingliste ein

Abonnieren

Neueste Beiträge

View on X