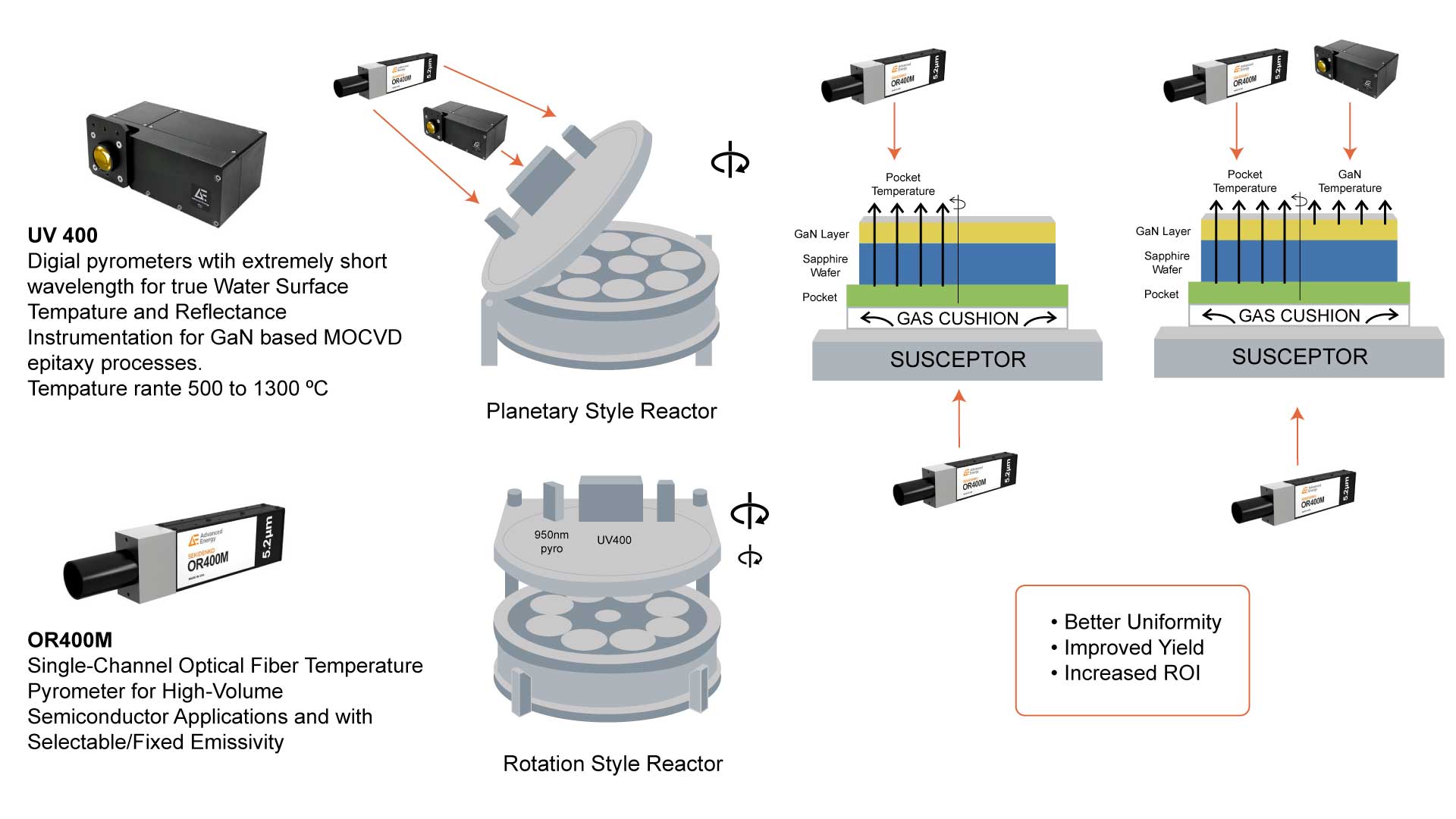

Mini/Micro LED MOCVD

Improving Yield for Mini/Micro LED Manufacturing

The MOCVD process plays a crucial role in the manufacturing of Mini and Micro LED displays, allowing for precise control over the epitaxial growth of LED structures. This process enables the production of high-quality LEDs with small pixel sizes, making them suitable for applications such as high-resolution displays, augmented reality devices, and other emerging technologies.

Advanced Energy’s UV 400 and UVR 400 pyrometers allow greater control of the process temperature to a variation of +/- 1 °C. By directly measuring wafer surface temperature, this improved method allows more accurate control of the wafer temperature leading to improved yield. These systems set a new standard for LED production processes, with results showing a reliable correlation between process temperature and final product wavelength.

.jpg)