Mikron MC320 Series

High-Performance, Infrared Camera for Demanding Real-Time Imaging Applications

Designed with advanced, maintenance-free electronics and industrial protective packaging, the Mikron® MC320 series offers unparalleled accuracy for demanding industrial and manufacturing applications. This includes vessels and furnaces, rolling processes, rotary kilns, quality monitoring in glass production, through-flame imaging in furnaces and boilers, and measurement of targets or objects with low emissivity. The MC320 series can be configured with flame-filtering capability for furnace and kiln monitoring.

Eigenschaften

- High performance, cost-effective complete monitoring solution

- Supports low and high temperature applications

- Optional industrial grade rugged enclosure

- Gigabit Ethernet communication

- Support for IO module, OPC, and Modbus through LumaSpec RT Control software

Vorteile

- Utilize turnkey solutions to meet the most severe and challenging thermal imaging system requirements

- Produce superior images and temperature measurement accuracy for mid-wave applications

- Take advantage of advanced maintenance-free electronics and industrial protective packaging

- Operate in harsh environments

- Better monitor a unique range of process monitoring applications using mid-wave infrared (MWIR)

Spezifikationen

| Betriebstemperaturbereich (°C): | 0 to 50 |

|---|---|

| Wellenlängenbereich (nm): | 3000-5000 |

| Optische Schnittstelle: | Manual Focus |

| Anzahl von Kanälen: | 1 |

| Genauigkeit: | ±2 deg C or 2% of reading |

| Messrate (Hz): | 9 Hz, 50 Hz |

| Sichtfeld: | 21° to 53° |

| Filter (µm): | 4.8 to 5.2 |

Zubehör

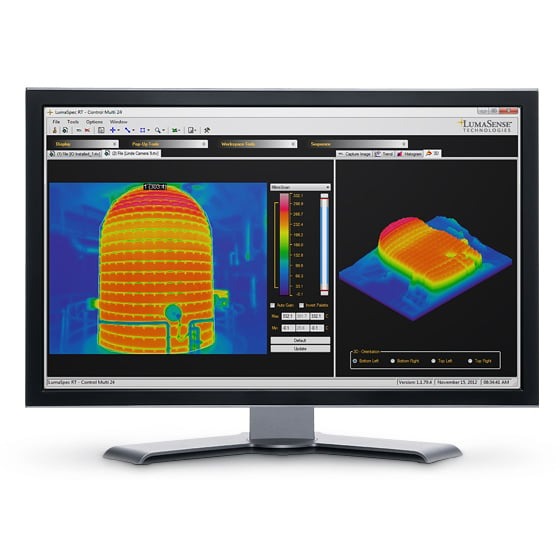

Mikron LumaSpec RT Software

Windows-Based, Real-Time Data Acquisition Software

Mikron Analog and Digital I/O-Module

RTV Control RT Software Extendable Module for Fixed-Installation Thermal Imagers

Mikron Spyglass and Viewports

Pinpoint Hotspots in Electrical Cabinets while Circuits are Energized and Under Load

Mikron VC Enclosure

Vortex-Cooled, Heavy-Duty, Industrial-Grade, Thermal Imager Protector

Mikron LumaSpec Offline Analyzer 5.0

Advanced Thermal Image Processing, Analysis, and Report-Writing Software

Technische Dokumentation

Verwandte Anwendungen

Alle Anwendungen erkundenDienstleistungen

Repair

Our worldwide service centers provide fast cycle times, use only AE-qualified parts, and follow the original product's specifications and test procedures for the highest quality repair or calibration.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Calibration and Alignment

Advanced Energy has the tools and processes to ensure your equipment continues to meet its original specifications. Our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Total Service Package

We offer customized service bundles that include calibration, alignment, and extended warranty. Services will include scheduled calibration with adjustment and repairs as needed. Any software/firmware upgrades are also made available for customers.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Field services and On-Site Training

Our field service engineers are available to support your on-site needs. We can properly secure and mount products, hook up your electrical connections, validate alignment and calibrate, and test to your specifications.