A Model for Reliability – Accelerated Life Tests at Advanced Energy

Posted August 09, 2018 by Michael Shover

We spend a lot of time thinking about how to make our products fail in the lab. We know that the more time, effort and thought we put into identifying failure modes during the early stages of development, the better the reliability of the end-state product. I’ll come right out and say what you are thinking: Every company understands that. Yet, some products are more reliable than others. Why?

We’ve recently written a white paper – Accelerated Life Test Principles and Applications in Power Solutions – that describes our methodology for making sure that the products we develop for our customers meet and often exceed their requirements. In it, we look at three of those components and the accelerated life tests we apply to semiconductors, passive parts and electromechanical parts.

While I encourage you to download your copy and dig in, let me describe what to expect, so you can know that what we’ve developed is of value to you.

We Set Tolerances Low, So Quality is High

Lead development engineers building complex products use many different parts and various types of parts. Consequently, test design necessitates the careful application of multiple acceleration models, as the aging of individual parts varies by failure mechanism.

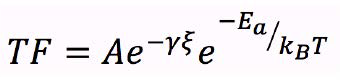

Our customers expect acceleration of the semiconductor design/production cycle to speed up the go-to-market schedule, while at the same time need to balance rapid development with long-term reliability. Our approach to that conundrum is to use well-known formulas to help estimate the affect of applied stresses including temperature, electric field, voltage and current density. We apply a form of the Arrhenius equation to describe exponential dependence:

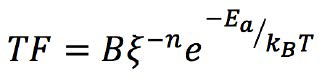

and a power-law dependence, expressed as:

where n = the power law exponent. The mechanism for degradation and eventual failure of a semiconductor device determines which dependence is the best fit.

Again, experienced design engineers know that this is a common methodology. What can vary, however, is the confidence bound. Our approach is to implement conservative metrics in this and other accelerated life tests. If you suspect that there is more to our ALT process, you are correct. Considering that this is a public forum, I’m not in a position to discuss our proprietary approach. What I can tell you is that we account for uncertainty by putting a low confidence bound on actual test results, always favoring caution.

In our whitepaper, we also discuss accelerated testing for passive parts such as resistors, inductors and capacitors. As a starting point, we use the Coffin-Manson equation to assess fatigue to solder joints.

![]()

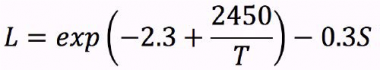

Our products typically have few moving parts. However, it’s common for electromechanical parts to fail more often than passive components. Cooling fans are an example. Since their reliability depends primarily on the bearing lubricant, we utilize the Booser equation:

where L = mean grease life and S = speed-related factor. I’m using this example to help drive home the point that we think about every element in complex systems, including the grease that lubes bearings. It’s one more element in comprehensive accelerated life tests that, when executed for all the components in a complex design, culminate in high quality products.

Full-Cycle Design Partner

Advanced Energy’s Reliability Engineering Team will collaborate with your engineers throughout the design cycle, from concept to release and through the product maturity cycle. We staff our team with experienced, innovative engineers who draw on decades of industry experience to make sure that best practices are integrated into the design techniques and that verification testing occurs exactly when and as often as needed. Our goals are your goals:

- Improve KPIs for lower total cost of ownership, increased throughput and minimal process downtime

- Get highly-engineered products to market quickly, but not at the expense of performance and reliablity

So, now, please download “Accelerated Life Test Principles and Applications in Power Solutions.” You’ll find that we aren’t even going to ask for your email address to access our work. Please take a few minutes to read it and of course get in touch with me or your sales representative to learn more.

.png?resizemode=force&maxsidesize=884)