Safety Requirements in Medical Equipment: Designing for BF and CF Classifications

Posted March 05, 2024 by Paul Kingsepp

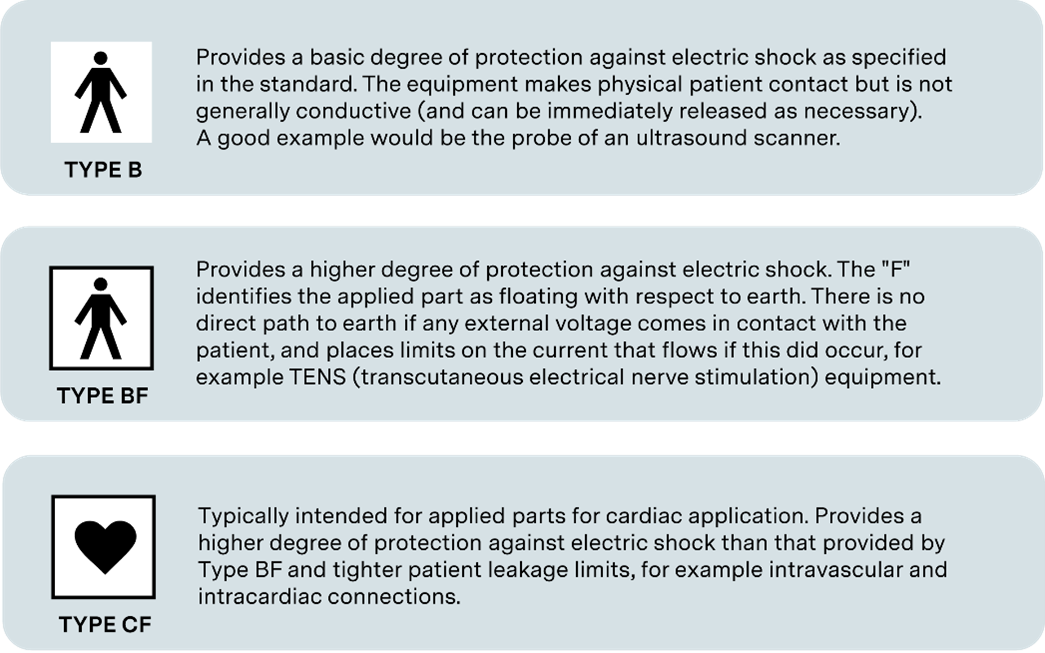

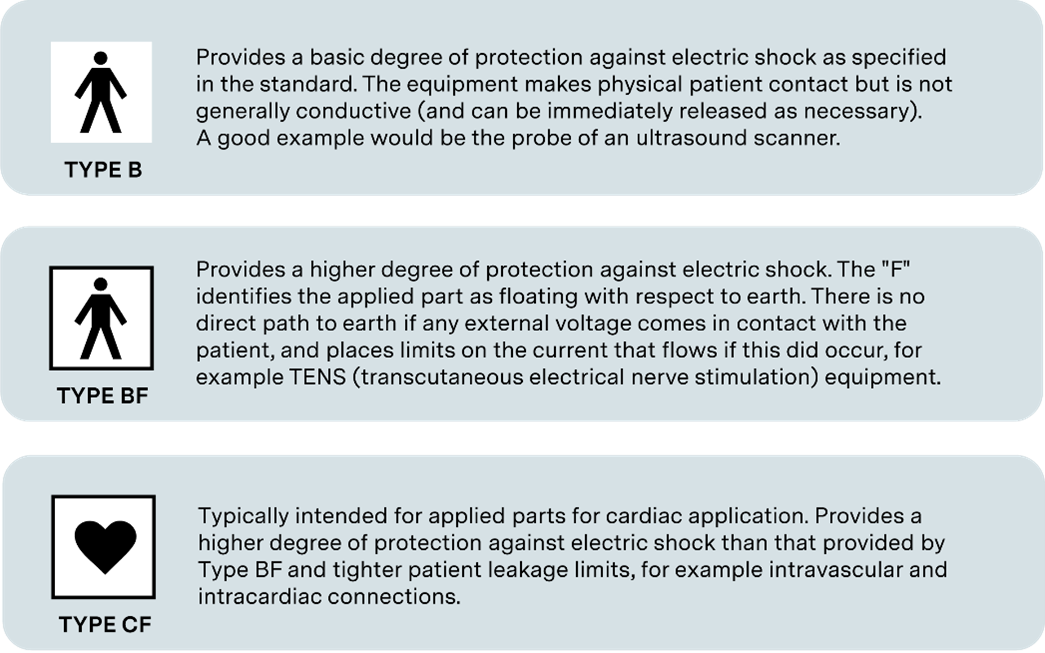

IEC 60601-1 is the most critical international safety specification for the design of medical electrical equipment. This standard defines classifications that impact safety-related design, which are based on how systems interact with patients.

Figure 1.1 IEC 60601-1 describes three safety categories based on type of contact with patient

If a patient accidentally comes in contact with the mains voltage, the ungrounded floating BF and CF categories will restrict the resulting current to a reasonably safe level to cause less harm. This is one of the distinctions between Type BF and CF and Type B, as in Type B, the current flowing may only be limited by the patient’s impedance. In applications where patient connections are low impedance or there is a fixed connection to the patient - such as in electrocardiogram (ECG) electrodes - Type B applied parts would not be appropriate.

When deciding on Type B or BF isolation, there should be consideration given as to if the equipment is intended to be used in isolation, especially if the requirement for the specific Type is not explicitly stated in the standard. Type B applied parts can offer an acceptable level of safety in cases where the patient is not connected to other electrical equipment or where additional protection is provided by isolated main supplies and residual current devices (RCDs). Type BF or CF applied parts offer an advantage in situations where multiple pieces of medical electrical equipment are used simultaneously, a scenario in which there is a higher risk of the patient coming in contact with mains voltages.

Type B, BF or CF?

When it comes to developing medical systems, it is important to understand the impact these categories have on power supply design. Selection is important for both safety and commercial reasons. Making the most appropriate choice ensures regulatory compliance and patient safety and optimizes the price-performance ratio in such a way that the final cost of equipment is commercially viable. Over-specifying by mandating the use of type BF or CF parts where type B is adequate, for example, could increase costs unnecessarily.

Depending on the category, an important element for IEC standard certification is ensuring that power supplies meet isolation and leakage current requirements. In terms of isolation, for example, the standard dictates that all equipment must offer minimum input-to-output isolation of 4,000 VAC and minimum input-to-ground isolation of 1,500 VAC. Minimum output-to-ground isolation is 500 VAC for Type B and 1,500 VAC for Type BF and Type CF.

Leakage currents in AC-connected power supplies are typically associated with capacitive coupling across power transformers and the Y-class filter capacitors that are connected to satisfy EMC regulations. IEC 60601 itself includes EMC specifications, which can present additional challenges, as reducing leakage in line with BF and CF requirements may preclude connecting filters on inputs. This leads to the possibility that a power supply may satisfy leakage requirements while the overall system leakage is excessive.

IEC 60601-1 specifies the maximum respective leakage currents to earth and to the equipment case under normal conditions as 500 µA and 100 µA, rising to 1 mA and 500 µA respectively for single fault conditions. However, when it comes to leakage currents that may flow through patients, the limits differ depending on equipment classification. For Type B and Type BF, maximum permitted leakage currents for normal and single-fault conditions are 100 µA and 500 µA respectively, falling to just 10 µA and 50 µA for Type CF.

Supporting Compliance and Design

Advanced Energy’s broad portfolio of standard power products for medical equipment are designed to make it easy for engineers to address IEC 60601-1 certification requirements. However, meeting a medical application’s criteria for functionality, performance and regulatory safety compliance is not always possible with off-the-shelf solutions and may require some level of customization. That’s why Advanced Energy offers standard products suitable for modification and modular AC-DC and DC-DC power supplies with many configurable options. Choosing these supplies can simplify design, reduce development time, and support rapid certification.

Figure 1.2 Power supplies that support BF and CF ratings

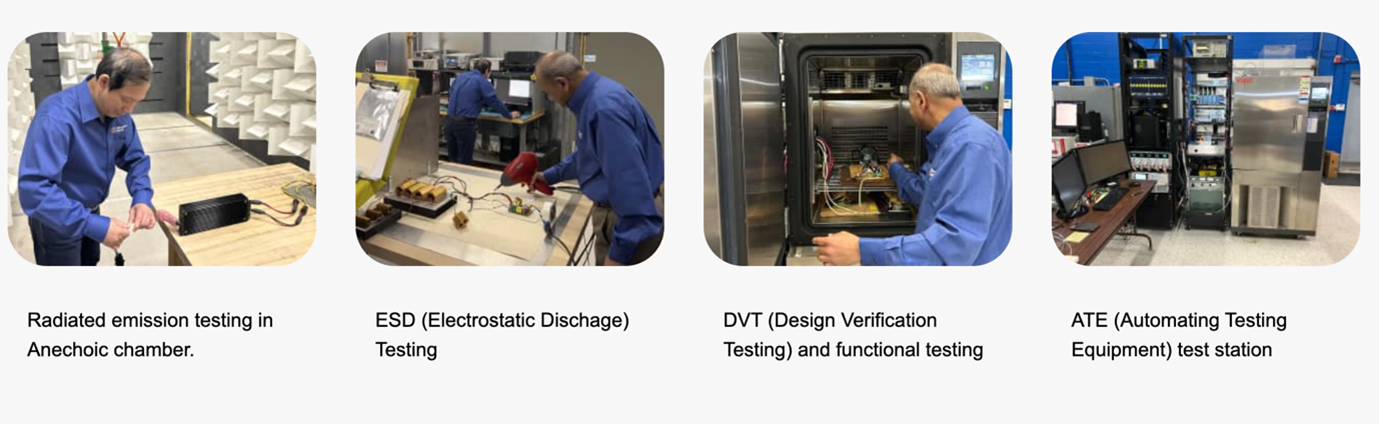

Advanced Energy also supports the development of full, turnkey solutions. Much of this work is done at Advanced Energy’s Customer Experience Centers (CECs) – global facilities that are staffed by engineers with many years of experience in medical systems.

Figure 1.3 CECs are staffed by engineers with direct experience of medical applications

At these CECs, Advanced Energy teams work with customers at the system level, guiding equipment designers through the development journey to deliver systems that are cost-optimized for target applications while meeting all performance, safety, and regulatory targets.

Figure 1.1 IEC 60601-1 describes three safety categories based on type of contact with patient

If a patient accidentally comes in contact with the mains voltage, the ungrounded floating BF and CF categories will restrict the resulting current to a reasonably safe level to cause less harm. This is one of the distinctions between Type BF and CF and Type B, as in Type B, the current flowing may only be limited by the patient’s impedance. In applications where patient connections are low impedance or there is a fixed connection to the patient - such as in electrocardiogram (ECG) electrodes - Type B applied parts would not be appropriate.

When deciding on Type B or BF isolation, there should be consideration given as to if the equipment is intended to be used in isolation, especially if the requirement for the specific Type is not explicitly stated in the standard. Type B applied parts can offer an acceptable level of safety in cases where the patient is not connected to other electrical equipment or where additional protection is provided by isolated main supplies and residual current devices (RCDs). Type BF or CF applied parts offer an advantage in situations where multiple pieces of medical electrical equipment are used simultaneously, a scenario in which there is a higher risk of the patient coming in contact with mains voltages.

Type B, BF or CF?

When it comes to developing medical systems, it is important to understand the impact these categories have on power supply design. Selection is important for both safety and commercial reasons. Making the most appropriate choice ensures regulatory compliance and patient safety and optimizes the price-performance ratio in such a way that the final cost of equipment is commercially viable. Over-specifying by mandating the use of type BF or CF parts where type B is adequate, for example, could increase costs unnecessarily.

Depending on the category, an important element for IEC standard certification is ensuring that power supplies meet isolation and leakage current requirements. In terms of isolation, for example, the standard dictates that all equipment must offer minimum input-to-output isolation of 4,000 VAC and minimum input-to-ground isolation of 1,500 VAC. Minimum output-to-ground isolation is 500 VAC for Type B and 1,500 VAC for Type BF and Type CF.

Leakage currents in AC-connected power supplies are typically associated with capacitive coupling across power transformers and the Y-class filter capacitors that are connected to satisfy EMC regulations. IEC 60601 itself includes EMC specifications, which can present additional challenges, as reducing leakage in line with BF and CF requirements may preclude connecting filters on inputs. This leads to the possibility that a power supply may satisfy leakage requirements while the overall system leakage is excessive.

IEC 60601-1 specifies the maximum respective leakage currents to earth and to the equipment case under normal conditions as 500 µA and 100 µA, rising to 1 mA and 500 µA respectively for single fault conditions. However, when it comes to leakage currents that may flow through patients, the limits differ depending on equipment classification. For Type B and Type BF, maximum permitted leakage currents for normal and single-fault conditions are 100 µA and 500 µA respectively, falling to just 10 µA and 50 µA for Type CF.

Supporting Compliance and Design

Advanced Energy’s broad portfolio of standard power products for medical equipment are designed to make it easy for engineers to address IEC 60601-1 certification requirements. However, meeting a medical application’s criteria for functionality, performance and regulatory safety compliance is not always possible with off-the-shelf solutions and may require some level of customization. That’s why Advanced Energy offers standard products suitable for modification and modular AC-DC and DC-DC power supplies with many configurable options. Choosing these supplies can simplify design, reduce development time, and support rapid certification.

Figure 1.2 Power supplies that support BF and CF ratings

Advanced Energy also supports the development of full, turnkey solutions. Much of this work is done at Advanced Energy’s Customer Experience Centers (CECs) – global facilities that are staffed by engineers with many years of experience in medical systems.

Figure 1.3 CECs are staffed by engineers with direct experience of medical applications

At these CECs, Advanced Energy teams work with customers at the system level, guiding equipment designers through the development journey to deliver systems that are cost-optimized for target applications while meeting all performance, safety, and regulatory targets.

Paul Kingsepp

Advanced Energy

As Advanced Energy’s Product Line Manager for open-frame products, Paul Kingsepp develops product strategy for the company’s broad range of AC-DC power supplies. Paul collaborates closely with engineers, designers, and market analysts to identify market trends, anticipate customer requirements, and drive product development initiatives from conception to launch. His ability to balance technical innovation with market demand has resulted in a portfolio of products that exceed customer expectations.

More posts by Paul Kingsepp