The Food Safety Modernization Act: It’s Time to Shift to a Proactive Stance in Your Food Manufacturing Facility

Posted December 07, 2016 by Advanced Energy Editor

The Origins of Food Safety Are Out of This World

The principles of Hazard Analysis and Critical Control Point (HACCP) originated in the NASA space program. NASA wanted food that wouldn’t crumble and affect control systems and would be safe for astronaut consumption. They already mandated the use of Critical Control Points (CCPs) in their design engineering process, but applying the same concepts to food production was new. This approach required food suppliers to start identifying “critical failure areas” and eliminate them from the system. This began the conversation and the new voluntary global industry standard was ready to be rolled out to an audience beyond NASA in 1971. In contrast, the Food Safety Modernization Act (FSMA) legislation was passed by Congress and signed into law in January 2011. It mandates Hazard Analysis and Risk-based Preventive Controls (HARPC) as the food processing industry’s regulatory standard.

Preventing Food Contamination From “Farm-to-Fork”

The FSMA marks a dramatic change in the intent and emphasis of U.S. food regulations that had been in effect for the past 70 years. Prior Food and Drug Administration (FDA) regulations required that food manufacturing facilities react to the outbreak of foodborne pathogens. The FSMA shifts their regulatory focus to a more proactive stance on preventing food contamination from “farm-to-fork”. Signed into law in 2011, the FSMA has just finalized and formulated their regulation and began implementation.

When Does the Regulatory Shift Take Place?

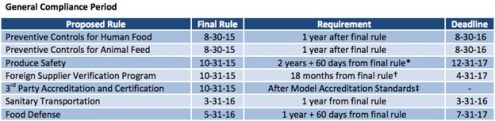

The Preventive Controls for Human Food deadline is August 30, 2016. According to the Association of Food, Beverage and Consumer Products Companies, the effective dates for the general compliance period are demonstrated in the chart below.

Implementation periods for small and very small businesses extend implementation by one year and two years, respectively.

Advanced Energy's TEGAM designs, manufactures and sells digital thermometers for the food industry, among other industries where our measuring instrumentation find useful homes. Our datalogger thermometers feature wireless Bluetooth® connectivity for Cloud storage access, while our thermocouple thermometers feature temperature probes for easy temperature monitoring. Contact us here for more information or to engage with our sale team for product purchases, please.