Top Trends from Glasstec 2024: Sustainability, Advancement of DC Power and Emerging Markets

Posted November 21, 2024 by Frank Sohn, Kyle Moore

Blog Summary:

Advanced Energy discusses top trends at Glasstec 2024:

1. Decarbonization: The glass industry is focusing on reducing its carbon footprint by transitioning from gas-fired ovens to electric-powered heating systems. AE's Thyro-PX® SCR controller and Impac® pyrometers are highlighted for their efficiency and precision in supporting these goals.

2. Power Supply Innovations: The shift from AC to DC power supply technology in glass coating processes offers improved arc management and process control. AE's Dynamic Reverse Pulsing (DRP) technology enhances deposition rates and reduces costs, showing promising results in production lines.

3. Emerging Markets: India's growing demand for energy-efficient and sustainable glass manufacturing technologies presents opportunities for new plants. AE's solutions, like SCR controllers and pyrometers

Advanced Energy discusses top trends at Glasstec 2024:

1. Decarbonization: The glass industry is focusing on reducing its carbon footprint by transitioning from gas-fired ovens to electric-powered heating systems. AE's Thyro-PX® SCR controller and Impac® pyrometers are highlighted for their efficiency and precision in supporting these goals.

2. Power Supply Innovations: The shift from AC to DC power supply technology in glass coating processes offers improved arc management and process control. AE's Dynamic Reverse Pulsing (DRP) technology enhances deposition rates and reduces costs, showing promising results in production lines.

3. Emerging Markets: India's growing demand for energy-efficient and sustainable glass manufacturing technologies presents opportunities for new plants. AE's solutions, like SCR controllers and pyrometers

The Advanced Energy (AE) team recently returned from Düsseldorf, Germany where we attended the biennial Glasstec trade fair. This event brought together the global glass manufacturing industry gathered to explore technologies, trends and challenges.

We connected with customers, partners and industry experts from all over the world and discussed the challenges they face as they seek to drive the industry forward.

The show highlighted technologies like low-E, electrochromic and display glass, emphasizing the global shift towards sustainability and decarbonization.

Below are three key trends from the event.

Trend 1: Decarbonization Takes Center Stage

The glass manufacturing process produces 86 million tons of CO2 per year. Therefore, glass manufacturers are working to reduce their carbon footprints in response to regulatory requirements and a commitment to sustainability. The industry is considering transitioning from traditional gas-fired ovens to electric-powered heating systems, starting with a hybrid solution that combines gas-fired furnaces with electrically powered heating technology.

This switch therefore has great potential to reduce the industry’s footprint

Silicon-controlled rectifier (SCR) power controller technology that deliver precise control and efficiencies of up to 99.5%, like AE’s 1 kV Thyro-PX® SCR controller, drew significant attention at the show.

By operating at higher voltages, the Thyro-PX reduces current requirements by 30-60% depending on the required voltage level. This high-performance solution supports the industry’s decarbonization goals by enhancing power efficiency and reducing both capital and operational expenses. AE’s complementary thermal sensing offering Impac® pyrometers deliver the precision for real-time optimizations regarding temperature measurement in the glass production process, ensuring manufacturers can meet increasingly stringent environmental standards.

We connected with customers, partners and industry experts from all over the world and discussed the challenges they face as they seek to drive the industry forward.

The show highlighted technologies like low-E, electrochromic and display glass, emphasizing the global shift towards sustainability and decarbonization.

Below are three key trends from the event.

Trend 1: Decarbonization Takes Center Stage

The glass manufacturing process produces 86 million tons of CO2 per year. Therefore, glass manufacturers are working to reduce their carbon footprints in response to regulatory requirements and a commitment to sustainability. The industry is considering transitioning from traditional gas-fired ovens to electric-powered heating systems, starting with a hybrid solution that combines gas-fired furnaces with electrically powered heating technology.

This switch therefore has great potential to reduce the industry’s footprint

Silicon-controlled rectifier (SCR) power controller technology that deliver precise control and efficiencies of up to 99.5%, like AE’s 1 kV Thyro-PX® SCR controller, drew significant attention at the show.

By operating at higher voltages, the Thyro-PX reduces current requirements by 30-60% depending on the required voltage level. This high-performance solution supports the industry’s decarbonization goals by enhancing power efficiency and reducing both capital and operational expenses. AE’s complementary thermal sensing offering Impac® pyrometers deliver the precision for real-time optimizations regarding temperature measurement in the glass production process, ensuring manufacturers can meet increasingly stringent environmental standards.

Figure 1. The Advanced Energy Thyro-PX

Figure 1. The Advanced Energy Thyro-PX

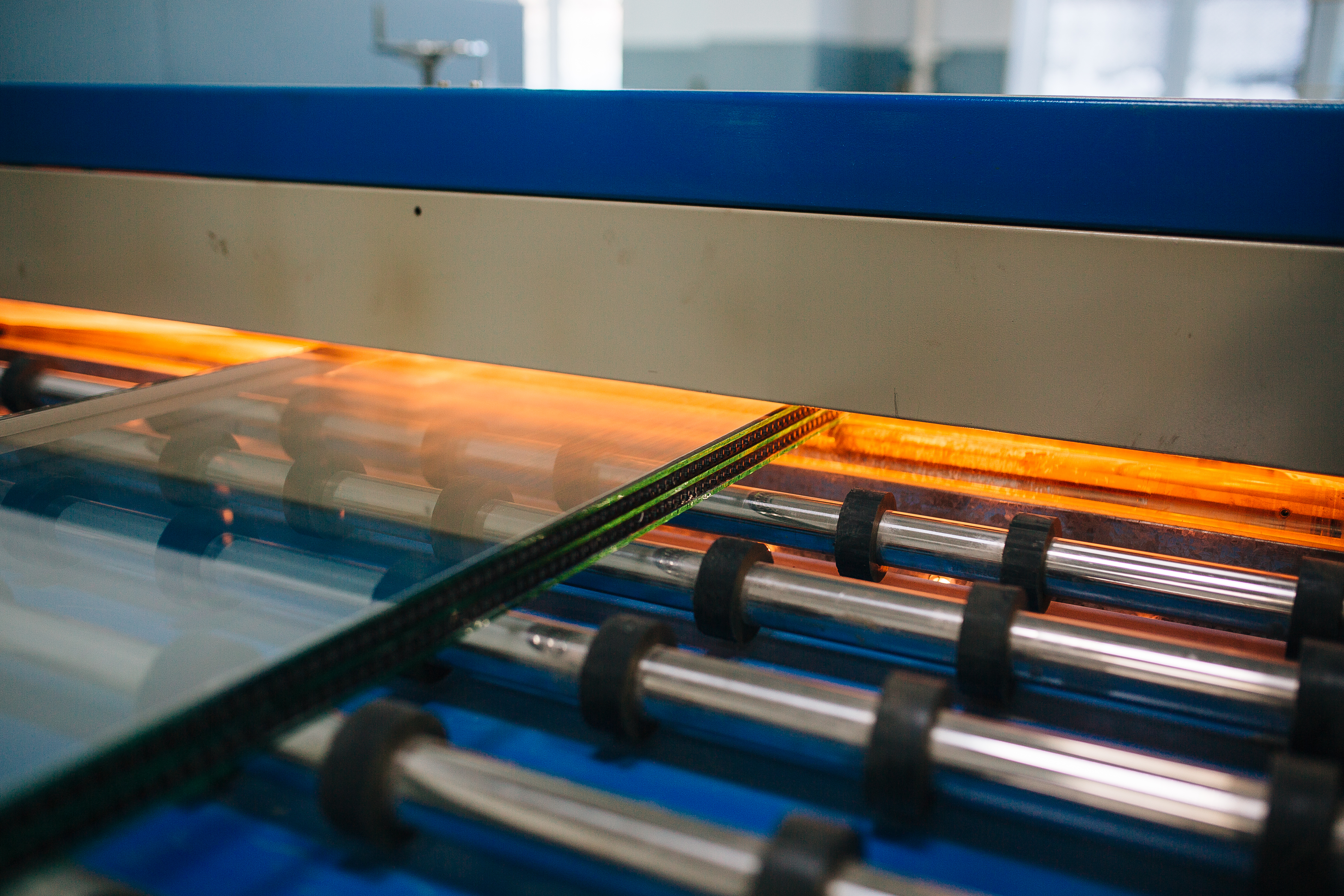

Trend 2: Power Supply Innovations Addressing Industry Challenges

Almost all types of glass have multiple layers of coatings done by plasma-based deposition process, and the transition from AC to DC power supply technology offers improved arc management, a smaller footprint, and increased process control for a variety of material applications. New coating facilities, particularly in Europe and North America, are now using DC. The existing base of older AC plasma power installations, such as those in China, presents a significant opportunity for retrofitting as manufacturers of coated glass consider updating their systems to the latest DC power supplies. For those considering upgrading their tools or replacing outdated AC technology, Advanced Energy application engineers have experience working with multiple customers on incorporating DC technology and are available to assist.

AE’s Dynamic Reverse Pulsing (DRP) technology garnered attention as a powerful solution that builds on proven DC technology. Compared to a conventional bipolar-DC setup, DRP increases the power delivered to each cathode, increasing deposition rate without increasing tool footprint. Higher deposition rates enable higher coated glass throughput and reduce capital expenditures for new installs and tool upgrades as demand for high quality coated glass continues to grow. Further, DRP is proven to reduce film stress for better layer adhesion and decrease substrate temperatures, reducing tool costs associated with temperature control. Glass customers that have adopted DRP in their production lines are showing promising results, in-line with test data from Advanced Energy’s Customer Solution Lab.

Trend 3: Emerging Markets and Growth Opportunities

A significant topic of discussion was India's glass industry, specifically its pressing need for dependable and energy-efficient technologies. The country's investment in renewable energy and sustainable architecture is driving a rapidly increasing demand, presenting an opportunity to establish new manufacturing plants that utilize more sustainable processes.

Advanced Energy’s solutions, such as SCR controllers, which can increase efficiency by reducing current requirement and pyrometers that allow real-time optimization capability, are ideally suited for these new markets, where regulatory pressures, sustainability demands, and, more importantly, a push to modernize production are driving change.

To find out more about Advanced Energy’s commitment to expanding partnerships and working closely with customers around the globe, please contact us here.

Almost all types of glass have multiple layers of coatings done by plasma-based deposition process, and the transition from AC to DC power supply technology offers improved arc management, a smaller footprint, and increased process control for a variety of material applications. New coating facilities, particularly in Europe and North America, are now using DC. The existing base of older AC plasma power installations, such as those in China, presents a significant opportunity for retrofitting as manufacturers of coated glass consider updating their systems to the latest DC power supplies. For those considering upgrading their tools or replacing outdated AC technology, Advanced Energy application engineers have experience working with multiple customers on incorporating DC technology and are available to assist.

AE’s Dynamic Reverse Pulsing (DRP) technology garnered attention as a powerful solution that builds on proven DC technology. Compared to a conventional bipolar-DC setup, DRP increases the power delivered to each cathode, increasing deposition rate without increasing tool footprint. Higher deposition rates enable higher coated glass throughput and reduce capital expenditures for new installs and tool upgrades as demand for high quality coated glass continues to grow. Further, DRP is proven to reduce film stress for better layer adhesion and decrease substrate temperatures, reducing tool costs associated with temperature control. Glass customers that have adopted DRP in their production lines are showing promising results, in-line with test data from Advanced Energy’s Customer Solution Lab.

Trend 3: Emerging Markets and Growth Opportunities

A significant topic of discussion was India's glass industry, specifically its pressing need for dependable and energy-efficient technologies. The country's investment in renewable energy and sustainable architecture is driving a rapidly increasing demand, presenting an opportunity to establish new manufacturing plants that utilize more sustainable processes.

Advanced Energy’s solutions, such as SCR controllers, which can increase efficiency by reducing current requirement and pyrometers that allow real-time optimization capability, are ideally suited for these new markets, where regulatory pressures, sustainability demands, and, more importantly, a push to modernize production are driving change.

To find out more about Advanced Energy’s commitment to expanding partnerships and working closely with customers around the globe, please contact us here.

Frank Sohn

Advanced Energy

Frank Sohn is the senior strategic marketing manager for Critical Sensing and Control (CSC) at Advanced Energy.

More posts by Frank Sohn

Kyle Moore

Advanced Energy

.jpg)

.jpg)