Why Partnership and a Good Power Supply Are So Important to SEMs

Posted December 12, 2017 by Advanced Energy Editor

I recently had the privilege of traveling to Asia with my friend and colleague from Advanced Energy’s HiTek product group, Gary Byfield. We visited some of AE’s partners that integrate HiTek’s EG353 electron gun high voltage power supply into their scanning electron microscope (SEM) products.

Vendors in the SEM manufacturing market are typically seeking to gain competitive advantage in multiple areas including:

- Improved resolution

- Smaller system/module size

- Ease-of-use

- Improved reliability

- Reduced cost of ownership

The interesting thing is that for each of these important areas, the design of the SEM’s high voltage power supply becomes critical. Whether it is the mean-time-between-failure (MTBF), the stability over time or the maximum amplitude of the ripple voltage, the high voltage supply has a huge impact on the success of the SEM system in the marketplace. In current SEMs – irrespective of thermionic, cold field or Schottky emission electron gun configuration – the performance of the high voltage supply has a direct relationship on the performance and resolution of the SEM tool itself.

Whilst there are many aspects of the supply that affect SEM performance, three of the most important are arguably ripple voltage, stability, and reliability (MTBF). Recent trends indicate that SEM manufacturers are demanding higher performance, smaller-footprint products that have increased power supply reliability. The simplified design, reduced internal component count and in-built diagnostics that verify performance provided Advanced Energy’s D³C technology create the additional value expected by our customers.

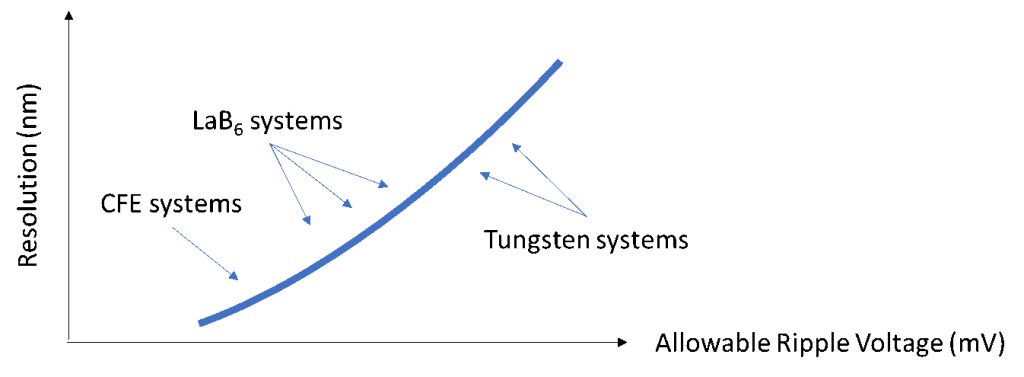

When it comes to ripple voltage, there is an interesting correlation between the ripple superimposed on the high voltage supply and the ultimate resolution of the SEM. As Gary explained in our Asia meetings, although the actual relationship is dependent upon many different variables, including electron gun configuration, acceleration voltage and column design, there exists a trend between ripple voltage and resolution that looks something like this…

As can be seen, if ultra-high resolutions are required, CFE electron gun configurations need to be used in conjunction with ultra-low ripple voltages – such that for resolutions of lower than 0.8nm, ripple voltages of less than 50mV at 35kV need to be achieved.

In summary, there are multiple factors surrounding the power supply that can mean the ultimate success or failure of an SEM tool – with reliability and ripple voltage being just two. To find out more information on features such as D³C technology and the EG353 that are setting the new standard for SEM power supplies, contact your local Advanced Energy sales representative.