How to Decrease the Error in Thermocouple Measurements

投稿 10月 09, 2018 によって Advanced Energy Editor

A simple change can improve the accuracy of your thermocouple measurements by over 75%.

The most common thermocouple type today is Type K. You see the yellow connectors everywhere. A type K thermocouple is an excellent thermocouple for higher temperature measurements typically over 315°C/600°F

If you are working below those temperatures, there are some options available to you that can cut your measurement errors by 50% or more.

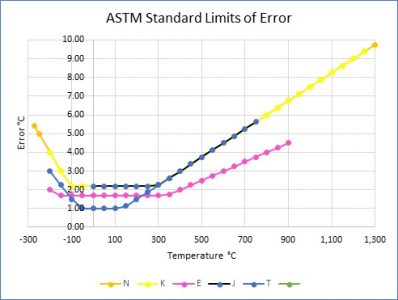

A standard Type K thermocouple has an error band of ±2.2°C/4.0°F for measurements below 293°C/559°F, above that it is ±0.75% of reading.

Simply by switching to a Type E thermocouple you can cut your error to ±1.7°C/3°F. That is a 22% decrease in error.

.jpg?lang=en-US)

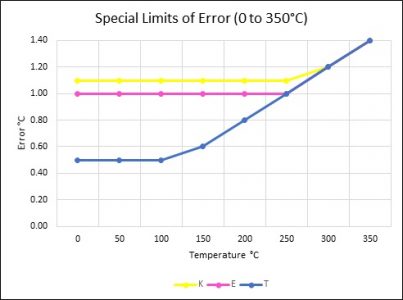

Using a “Special Limits of Error” (SLE) grade Type E probe further reduces the error to ±1°C/1.8°F. That is a 55% decrease in error bandwidth, and you can still measure up to 340°C/644°F with those accuracies. Type E error above 340°C to 900°C is ±0.5%, still 33% more accuracy than a Type K thermocouple.

For Temperatures below 133°C/270°F you can switch to a Type T thermocouple. This temperature range covers many Food Safety related processes. The standard limits of error for a Type T thermocouple IS the same as the SLE grade Type E ±1.8°C/3°F. Going to an SLE Type T thermocouple will reduce the error band by 50% more to ±0.5°C/0.9°F.

If you are working in these lower temperatures, you have reduced the error band from ±2.2°C/4.0°F for a type K thermocouple all the way down to ±0.5°C/0.9°F by switching to a Type T Special Limits of Error probe; a 77% decrease in the measurement error.

See all of TEGAM’s thermocouple thermometers here.

Please contact TEGAM with any questions you have on our products.