Improving Scrap Steel Efficiency with Arc Furnace Optimization Techniques

投稿 3月 26, 2025 によって Michael Becker

Blog Summary

1. Environmental Impact of Steel Production: Steel production is highly energy-intensive and contributes significantly to global CO2 emissions. Recycling scrap steel is much more efficient, reducing energy consumption and emissions substantially.

2. Electric Arc Furnaces (EAF) versus Traditional Blast Furnaces: EAFs, which remanufacture scrap steel, are a lower-emission alternative to traditional blast furnaces. They are gaining popularity due to their efficiency and lower environmental impact, especially when powered by renewable energy sources.

3. Technological Advancements in EAFs: Advanced technologies like silicon-controlled rectifiers (SCRs) and Advanced Energy’s Thyro-PX® modular solution enhance the efficiency, control and scalability of EAFs, making them a more viable option for modern steel production.

1. Environmental Impact of Steel Production: Steel production is highly energy-intensive and contributes significantly to global CO2 emissions. Recycling scrap steel is much more efficient, reducing energy consumption and emissions substantially.

2. Electric Arc Furnaces (EAF) versus Traditional Blast Furnaces: EAFs, which remanufacture scrap steel, are a lower-emission alternative to traditional blast furnaces. They are gaining popularity due to their efficiency and lower environmental impact, especially when powered by renewable energy sources.

3. Technological Advancements in EAFs: Advanced technologies like silicon-controlled rectifiers (SCRs) and Advanced Energy’s Thyro-PX® modular solution enhance the efficiency, control and scalability of EAFs, making them a more viable option for modern steel production.

Steel continues to play a crucial role in modern engineering and construction. However, steel requires enormous amount of energy to produce and each ton of steel production generates an average of 1.89 tons of carbon dioxide (CO2)—about 8% of global emissions (World Steel Association). As steel customers strive to improve the costs and energy efficiency of their production and decarbonize their supply chains, they face significant challenges in remaining competitive.

Recycling scrap steel is significantly more efficient, consuming 72% less energy per ton produced and reducing CO2 emissions by 58%, air pollution by 86%, water pollution by 76%, and water usage by 40% (EU).

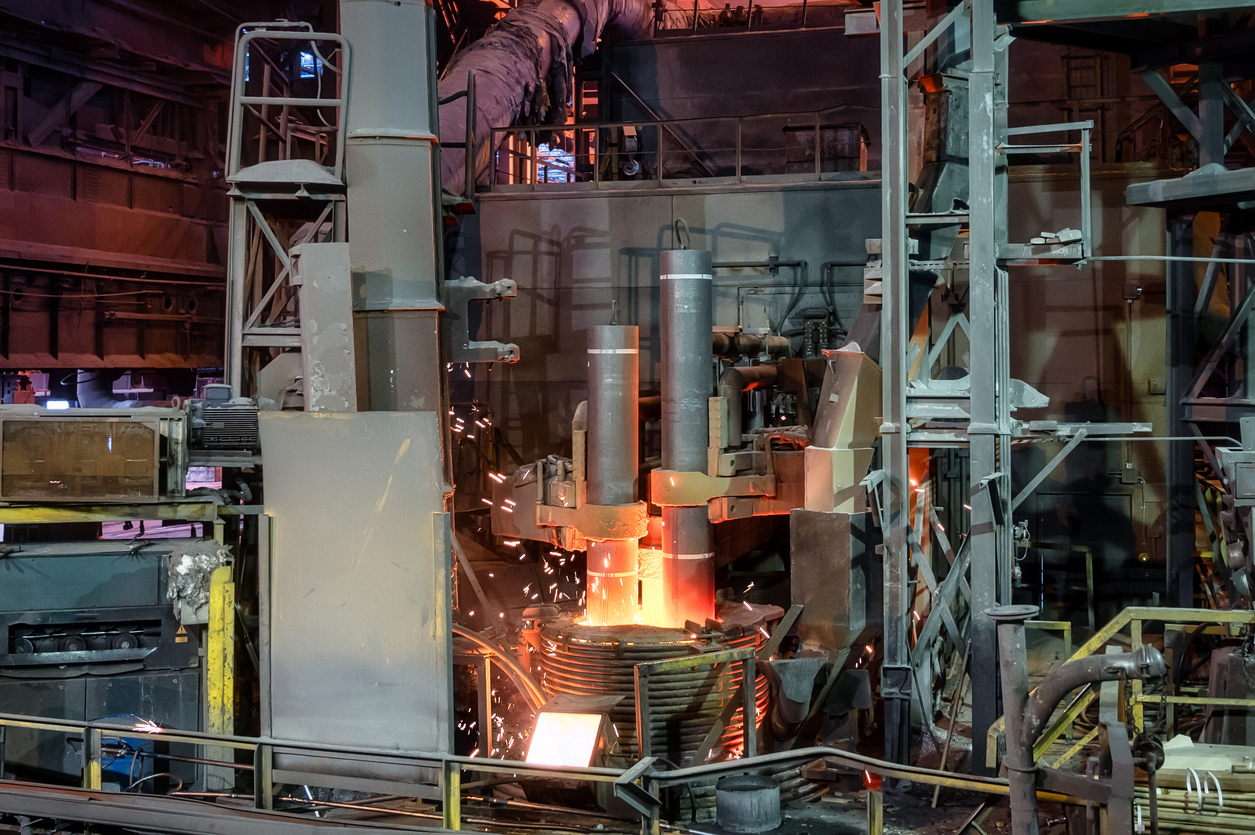

The core of steelmaking, whether recycled or virgin, is the furnace. Traditional blast furnaces are highly energy and carbon-intensive, often consuming large quantities of coal. However, electric arc furnaces (EAF) remanufacture scrap steel through a lower-emission process.

The greatest potential for EAF deployment lies in China, the world's largest steel producer. In 2020, China produced 57% of the world's crude steel, but only 9% came from EAFs, significantly lower than the global average of 26% (IEEFA).

The industry is nearing a critical juncture as many existing blast furnaces are set to reach the end of their operational lifespan by 2030. In major steel-producing countries such as China, U.S., EU, and Japan, over 75% of these furnaces will be impacted (pwc). One option is to re-line these furnaces to extend their use, but this would be a futile investment if governments enforce net-zero emissions initiatives, rendering them obsolete. Although green hydrogen presents some opportunities, achieving cost-competitive, large-scale utilization remains years away.

Compared to other techniques like the blast furnace/basic oxygen furnace (BF-BOF) and direct reduced iron (DRI), scrap-EAF (also called ‘secondary steelmaking’) is a simple process where scrap steel is heated and melted to produce new steel. The simplicity of this process also requires far fewer personnel, thereby further reducing costs. In addition, the scrap-EAF process can relatively low emissions if powered by electricity from renewable sources. From a cost perspective, it is already competitive with BF-BOF, and this competitiveness will increase as the cost of renewable electricity continues to decrease.

EAFs are already gaining popularity. In 2020, 71% of the total crude steel in the U.S. came from EAFs (IEEFA). The EU currently has 114 EAF plants primarily located in Italy, Spain and Germany with a combined production capacity of 80 million tons. However, so far, only 42% of steel made in the EU comes from EAFs. In Asia, rates are far lower.

The melting point of scrap steel is roughly 1,520°C. To achieve this melting point, the theoretical absolute minimum energy required to melt a ton of scrap steel is 300 kWh (Power Quality), although in reality, an EAF will typically require 440 kWh per ton of steel. Clearly, significant electrical energy must be delivered and controlled reliably to ensure high quality EAF steel.

While there are several technologies available for power conversion, silicon-controlled rectifiers (SCRs) are the preferred choice. Compared to technologies like insulated gate bipolar transistors (IGBTs), SCRs are significantly more efficient, often approaching 99.5%. At the 440 kWh per ton required for an EAF, every percentage point of efficiency represents over 4 kWh per ton of loss.

Advanced Energy’s Thyro-PX® Modular Solution includes a variety of components that allow operators of EAFs to custom configure, design and build liquid-cooled power stacks and control units. These components are optimized to meet the specific requirements of their processes, providing power to the heating elements.

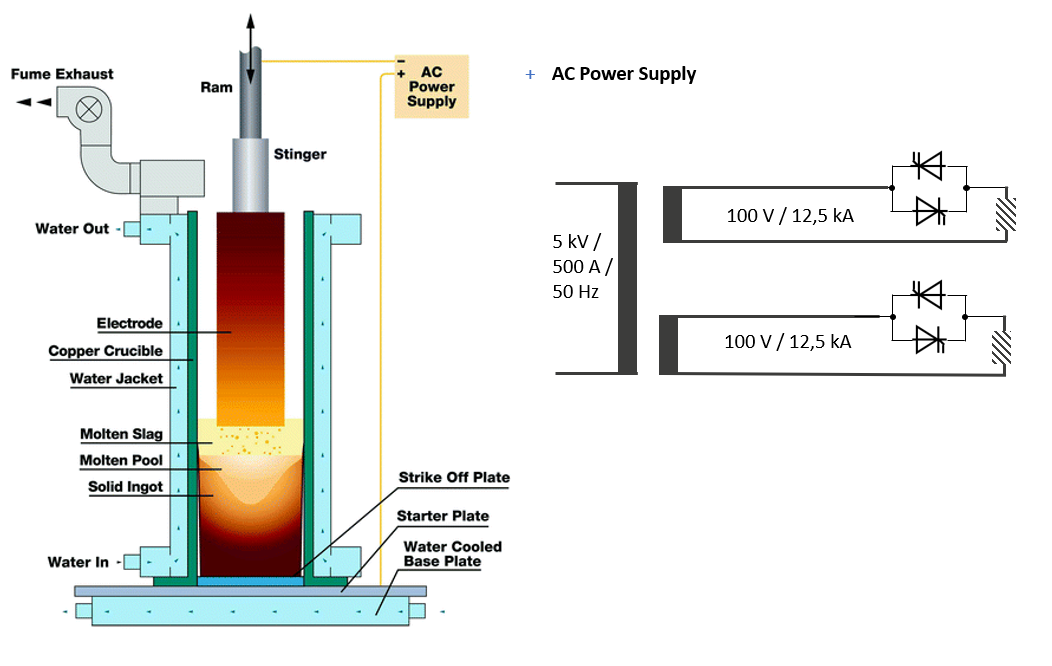

Fig. 1 The schematic above refers to a simple connection with:

- Water-cooled high power stacks for parallel connection

- One control unit for three parallel high-power stacks in one phase for maximum 12.5 kA

- Separation of control signals and high current by means of optional fiber optics interfaces.

The Thyro-PX solution leverages an SCR-based design to enhance efficiency, control, and power regulation. SCRs enable phase angle control of power, allowing for more efficient and precise management of the heating process compared to the standard thyristor-based approach. This leads to reduction in operational costs and CO2 emissions.

Scalability is achieved through a wide range of single, dual and three-phase off-the-shelf solutions. Thyro-PX units are highly accurate to ±0.5% voltage / current or ±1.0% power, meeting the requirements for stability and repeatability within steel manufacturing. Individual units can provide up to 5,000 A of current from a line voltage of 690 VAC (750 VDC). Optionally, 1,000 V units are available where it is important to reduce currents in busbars.

Communication between the control and power stacks is facilitated by an optional fiber optic trigger interface card, which ensures precise isolation between the control and power sections. By using a modular architecture, the systems can separate the control and power functions, thereby eliminating EMC issues.

Each Thyro-PX control unit can drive up to three high-power water-cooled Thyro-PX stacks arranged in parallel to supply the heating elements in an EAF. The controllers feature an Anybus digital interface card for connectivity to many popular protocols including Ethernet / IP, EtherCAT, PROFIBUS DPV1, PROFINET, and Modbus TCP/IP. For localized control, a Thyro-Touch 2.8” display allows intuitive operation and records up to six process parameters.

For further information on the Thyro-PX Modular Solution and its use in electric arc furnaces please visit Steel & Metals | Advanced Energy.

Michael Becker

Advanced Energy

Michael Becker is a product manager within System Power at Advanced Energy.

その他の投稿 Michael Becker