When High Voltage Amplifiers are a Better Choice than Power Supplies

投稿 9月 24, 2024 によって Tim Rushlow

Although a high-voltage amplifier (HVA) and a high-voltage power supply (HVPS) share similar voltage and current specifications, they have different roles. HVAs offer unmatched versatility and control from power supplies that make them valuable in many applications, especially in the research and development (R&D) phase of product development. This article explores when it is optimal to choose an HVA over an HVPS.

Overview of HVAs and HVPSs

HVPSs provide a reliable, consistent DC output to power devices and systems, excelling in steady-state applications. However, they struggle with dynamic loads or time-varying signals, unless properly optimized for the application. HVPSs also fall short when complex or rapidly changing voltage requirements are involved.

On the other hand, HVAs are designed to convert an AC signal from one power level to another. This ability to amplify time-varying signals allows HVAs to operate over a wide range of frequencies and conditions. HVAs also operate in all four quadrants of a voltage-current (V-I) plot, managing both positive and negative voltages and currents, making them ideal for capacitive or inductive loads.

.jpg)

Figure 1. Examples of Advanced Energy’s high voltage amplifiers

Choosing HVA or HVPS

For many applications the power supply requirements for product development are simple and easier to define. Therefore, many R&D teams opt for HVPSs during initial product design due to their availability, smaller size, and lower cost. However, this can be a mistake.

As an example, during R&D, performance requirements for HVPSs are not always clear, specifically on how to bring the most value to the application. HVAs provide precise control over voltage and current, allowing engineers to experiment with various load conditions and determine the necessary characteristics for the final power supply.

Starting with an HVA offers several advantages, including flexibility. HVAs enable engineers to explore different scenarios and understand how a system behaves under varying conditions.

Additionally, HVAs deliver enhanced control and give a dynamic response, operating in all four quadrants of the V-I plot. This capability allows them to handle complex loads, such as capacitive or inductive loads, and adjust quickly to changing conditions. This is crucial for characterizing system responses to rapid changes (such as voltage ramp-up or ramp-down) and assessing load tolerance.

HVAs also typically include current monitoring capabilities to help understand the dynamic response of loads under various conditions, such as different discharge rates, helping to fine-tune the final power supply characteristics to meet applications requirements.

When to Invest in an HVA?

While HVAs are larger and more expensive than HVPSs, the investment is justified for applications involving complex loads, dynamic conditions, and precise control. HVAs enable thorough experimentation and characterization during R&D, leading to optimal HVPS specifications and better performance in the final product.

HVAs are critical in applications where a dynamic response is essential, such as electrophoresis, electro-optic modulation, material poling, electrostatic deflection and AC-DC biasing. They provide valuable insights for applications demanding complex voltage control, like electrostatic chucking and 3D printing.

For many applications the power supply requirements for product development are simple and easier to define. Therefore, many R&D teams opt for HVPSs during initial product design due to their availability, smaller size, and lower cost. However, this can be a mistake.

As an example, during R&D, performance requirements for HVPSs are not always clear, specifically on how to bring the most value to the application. HVAs provide precise control over voltage and current, allowing engineers to experiment with various load conditions and determine the necessary characteristics for the final power supply.

Starting with an HVA offers several advantages, including flexibility. HVAs enable engineers to explore different scenarios and understand how a system behaves under varying conditions.

Additionally, HVAs deliver enhanced control and give a dynamic response, operating in all four quadrants of the V-I plot. This capability allows them to handle complex loads, such as capacitive or inductive loads, and adjust quickly to changing conditions. This is crucial for characterizing system responses to rapid changes (such as voltage ramp-up or ramp-down) and assessing load tolerance.

HVAs also typically include current monitoring capabilities to help understand the dynamic response of loads under various conditions, such as different discharge rates, helping to fine-tune the final power supply characteristics to meet applications requirements.

When to Invest in an HVA?

While HVAs are larger and more expensive than HVPSs, the investment is justified for applications involving complex loads, dynamic conditions, and precise control. HVAs enable thorough experimentation and characterization during R&D, leading to optimal HVPS specifications and better performance in the final product.

HVAs are critical in applications where a dynamic response is essential, such as electrophoresis, electro-optic modulation, material poling, electrostatic deflection and AC-DC biasing. They provide valuable insights for applications demanding complex voltage control, like electrostatic chucking and 3D printing.

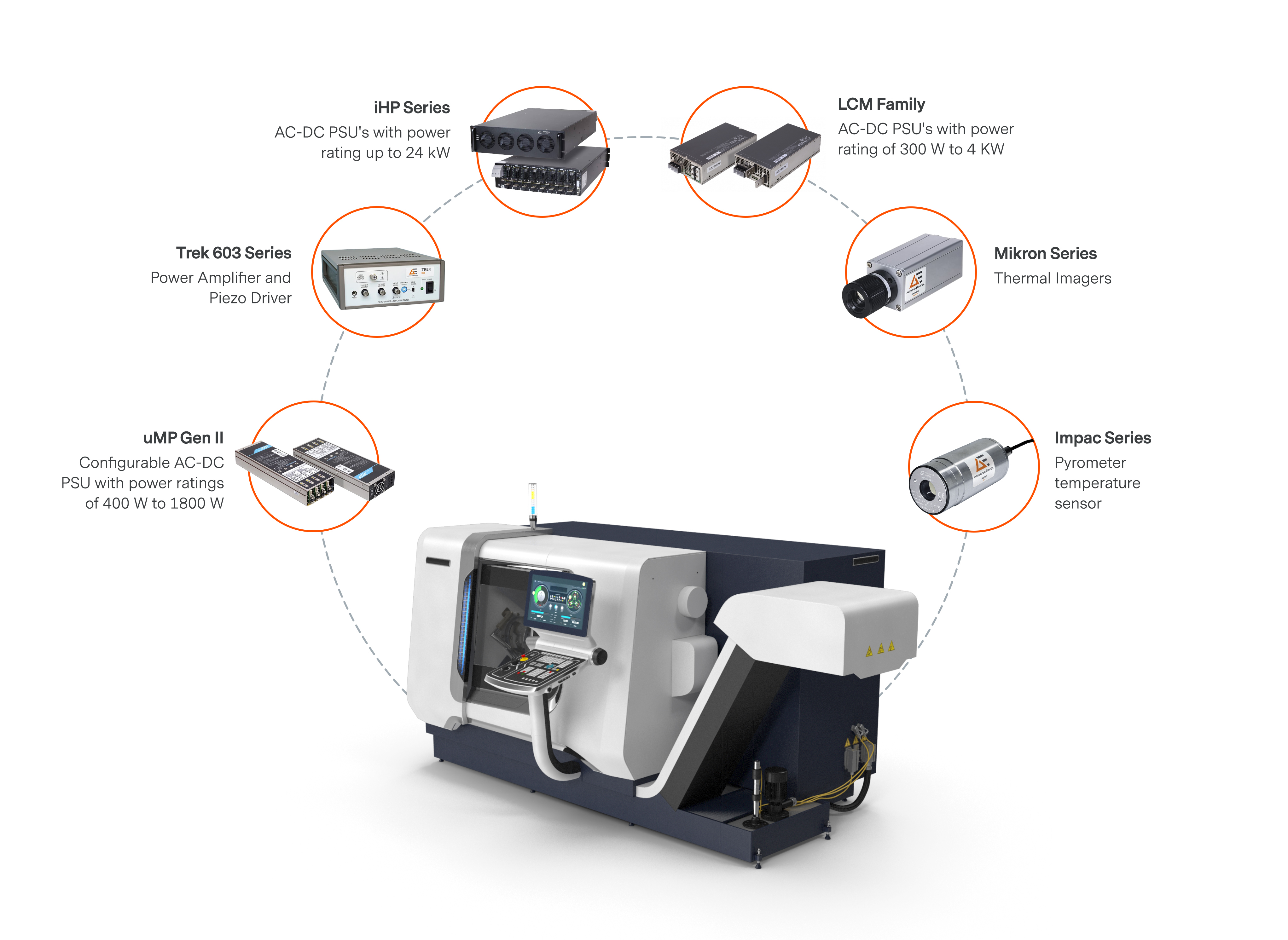

Figure 2. High voltage amplifiers are used in applications such as 3D printing

Figure 2. High voltage amplifiers are used in applications such as 3D printing

Case Study: Electrostatic Levitation Furnace (ELF)

An electrostatic levitation furnace (ELF) used in materials science research requires precise control to maintain stable levitation while varying the heating current. To maintain the stable levitation while varying the heating current, this process demands a precise level of control that is impossible with an HVPS. While the dynamic response of the HVA enables optimal operating conditions and ensures that even small changes in the material's properties or position can be compensated for immediately. As an example, an ELF on the International Space Station (ISS) contains an Advanced Energy’s Trek® high voltage amplifier.

An electrostatic levitation furnace (ELF) used in materials science research requires precise control to maintain stable levitation while varying the heating current. To maintain the stable levitation while varying the heating current, this process demands a precise level of control that is impossible with an HVPS. While the dynamic response of the HVA enables optimal operating conditions and ensures that even small changes in the material's properties or position can be compensated for immediately. As an example, an ELF on the International Space Station (ISS) contains an Advanced Energy’s Trek® high voltage amplifier.

Figure 3. Advanced Energy’s Trek high voltage amplifier Learn more about HVAs at Advanced Energy

Figure 3. Advanced Energy’s Trek high voltage amplifier Learn more about HVAs at Advanced EnergyAdvanced Energy offers a wide range of HVAs, both sub 5 kV and higher voltage (5 to 50 kV) amplifiers. These are available with customized service bundles including calibration. To find out more, or to download technical specification and data sheets please visit the Trek high voltage amplifier page.

Tim Rushlow

Advanced Energy

Tim Rushlow joined Advanced Energy in 2018 with the acquisition of Trek, Inc. Over 31 years at Trek, Tim was a product design engineer and R&D Manager. After joining Advanced Energy, Tim took on the role of Sr. Engineering Manager before translating his product and application experience into his current role as Senior Customer Solutions Engineer.

Tim holds a Bachelor of Science in Electrical Engineering from State University of New York at Buffalo.

その他の投稿 Tim Rushlow

Tim holds a Bachelor of Science in Electrical Engineering from State University of New York at Buffalo.