Pushing the Limits to Design for Reliability – Advanced Energy Worst-Case Circuit Stress Analysis

게시됨 10월 23, 2018 으로 Michael Shover

It’s our job to design power solutions that enable our customers to achieve new levels of performance in their processes and devices. Getting to that end goal starts in the early stage of development with deep engineering of electronic circuits and components.

We recently developed a whitepaper titled, “Design for Reliability Techniques – Worst-Case Circuit Stress Analysis” that provides insight on one of our methodologies for determining the reliability of components. In it, we discuss our unique approach to the well-known “design for reliability” process, the upfront analysis critical to identifying and mitigating risks to circuits, components and, by extension, our customers’ systems.

Just as I did with our blog post on what we cover in the first whitepaper in this series – Accelerated Life Test Principles and Applications in Power Solutions – read on to get insight on how the collaborative effort and experience we bring to our power solutions drives better reliability and performance in your applications, under all conditions.

Test Early, Test Often

The most revealing method for quantifying the design margins of electronic circuits is a Worst-Case Circuit Stress Analysis (WCCSA), which determines the stress levels on each component when all variable parameters are at values that maximize stress on the component being analyzed. It’s important to keep in mind that there really is not a single “worst case.” A WCCSA actually is the culmination of iterative analysis in which circuits are simulated in a variety of ways, data is analyzed, the design is modified and evaluated again, until the desired design margin is achieved. So, we look at a lot of worst cases.

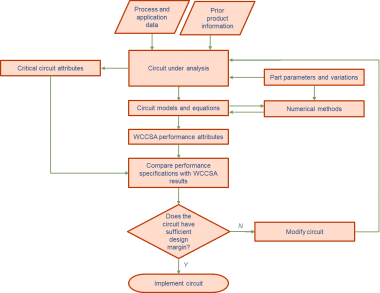

We’ve adapted our process to be specific to our needs, borrowing the core process from NASA’s Jet Propulsion Laboratory and the DoD’s Reliability Analysis Center. You can see in the flow diagram that we start with tolerance data, including parasitic and desired parameters, and utilize numerical analysis (Monte Carlo and others). We also use custom spreadsheets populated with data acquired from real-world customer applications. Then, we compare what we learn with performance specs. We then go back to the digital drawing board, alter the design and run more simulations.

Early Detection Leads to Design “Cures”

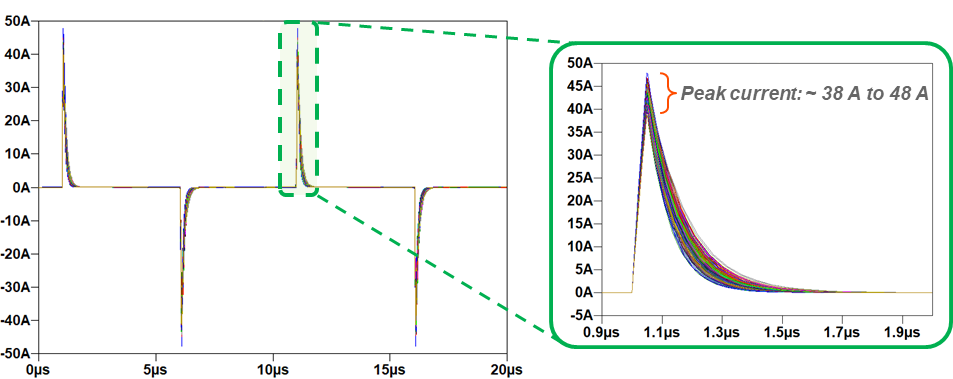

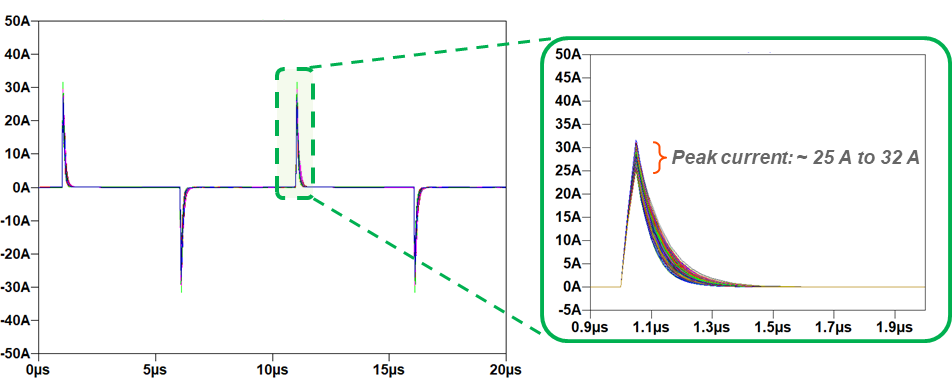

The value of a design for reliability paradigm lies in pinpointing performance issues long before investing in prototypes. I mentioned that we rely on simulations (circuit simulation, numerical computing and statistical analysis tools) in our WCCSA testing. Here’s an example, a 200-run simulation of pulsed current through a new electrolytic capacitor to determine performance degradation over time. The top image shows simulation of peak current through a new electrolytic capacitor; the bottom shows simulated peak current of an older capacitor. Is the drop of nearly 50 percent outside design tolerances? Maybe, maybe not. But it sure is a red flag.

And as I also said before, WCCSA doesn’t isolate a single variable or stress factor on a circuit. High voltage stress, currents, ambient temperatures, operating frequencies and other factors individually and in combinations are accounted for. By methodically running virtually every scenario for stress that a component will encounter during field use, we are able to implement design remedies early on.

The Human Element

You could argue that aside from proprietary data we’ve amassed over years of partnership with industry leaders, our competitors could and probably are doing similar WCCSA work. While momentarily putting aside the “proprietary data and industry leader” part, I’ll agree. That begs the question: What makes Advanced Energy WCCSA different? The answer is that we have an in-house staff of very experienced, innovative and always-questioning people who collaborate across several disciples. The point is that even with all the technology tools we have, the people using those tools make the difference.

Engineers are often skeptical about statements like what I’ve just made, but I’ll stand behind it. You’ll also see in our latest whitepaper a completely academic discussion of our WCCSA, and a lot more examples.

So, please download “Design for Reliability Techniques – Worst-Case Circuit Stress Analysis.” You’ll find that we aren’t even going to ask for your email address to access our work. Please take a few minutes to read it and of course get in touch with me or your sales representative to learn more.

.png?resizemode=force&maxsidesize=884)