Enabling advances in next-generation aesthetic laser systems

已发布 四月 21, 2025 由 Dermot Flynn

Blog Summary

• Market Growth and Drivers: The medical laser market is expanding due to increased adoption of non-invasive procedures driven by lifestyle changes, higher incidence of skin damage, and reduced procedural costs. The aging population and rise in medical tourism are also contributing factors.

• Technological Advancements: There is a shift from standalone lasers to multiplatform systems that combine laser, IPL, and RF technologies. These systems offer flexibility for combination therapies and treating multiple conditions, but they also present technical and regulatory challenges.

• Innovations in Power Supply: The new FlexiCharge series, particularly the FC4000, addresses size, weight, and efficiency challenges by combining capacitor charging and system power into a single compact unit. This innovation simplifies compliance with safety and EMI standards, reduces noise, and speeds up treatment times and market readiness.

• Market Growth and Drivers: The medical laser market is expanding due to increased adoption of non-invasive procedures driven by lifestyle changes, higher incidence of skin damage, and reduced procedural costs. The aging population and rise in medical tourism are also contributing factors.

• Technological Advancements: There is a shift from standalone lasers to multiplatform systems that combine laser, IPL, and RF technologies. These systems offer flexibility for combination therapies and treating multiple conditions, but they also present technical and regulatory challenges.

• Innovations in Power Supply: The new FlexiCharge series, particularly the FC4000, addresses size, weight, and efficiency challenges by combining capacitor charging and system power into a single compact unit. This innovation simplifies compliance with safety and EMI standards, reduces noise, and speeds up treatment times and market readiness.

The medical laser market includes laser technologies for surgeries, ophthalmology, and aesthetic treatments. This category covers cosmetic treatments, including scar and wrinkle removal, mole removal, hair removal, tattoo removal, and pigmented skin treatment. The adoption of these non-invasive procedures is increasing. Drivers include lifestyles changes, increased incidence of skin damage and general reduction in procedural costs. With an increasing aging population and a rise in medical tourism, there a greater awareness than ever of aesthetic procedures.

Traditionally, the equipment used for these procedures has been standalone lasers. However, there is an increasing level of multiplatform systems being developed that incorporate laser, intense pulsed light (IPL) and radio frequency (RF). Multiplatform lasers provide clinicians with the flexibility of several standalone systems in a single system, enabling combination therapies or treatment addressing several conditions.

System designers face many challenges when developing the next generation of multiplatform aesthetic lasers. These include technical and regulatory challenges as well as patient care and comfort along with clinician ease of use. In an increasing competitive market space, system designers must also meet shorter development cycles, while not compromising on performance. Selecting the right power supply is critical to ensure that design targets are achieved.

Size and weight

From a purely physical perspective, size and weight are critical. Multiplatform systems are often mobile and are generally located in clinics where space is at a premium. This has a direct impact on the size and weight of the system. Traditionally, the system had one power supply for capacitor charging (for laser and IPL), and another power supply for all the system electronics (pumps, cooling elements, monitors, microprocessors, etc.). Both power supplies are critical components and have their own input cabling, EMI filtering, etc., which take up valuable system real estate.

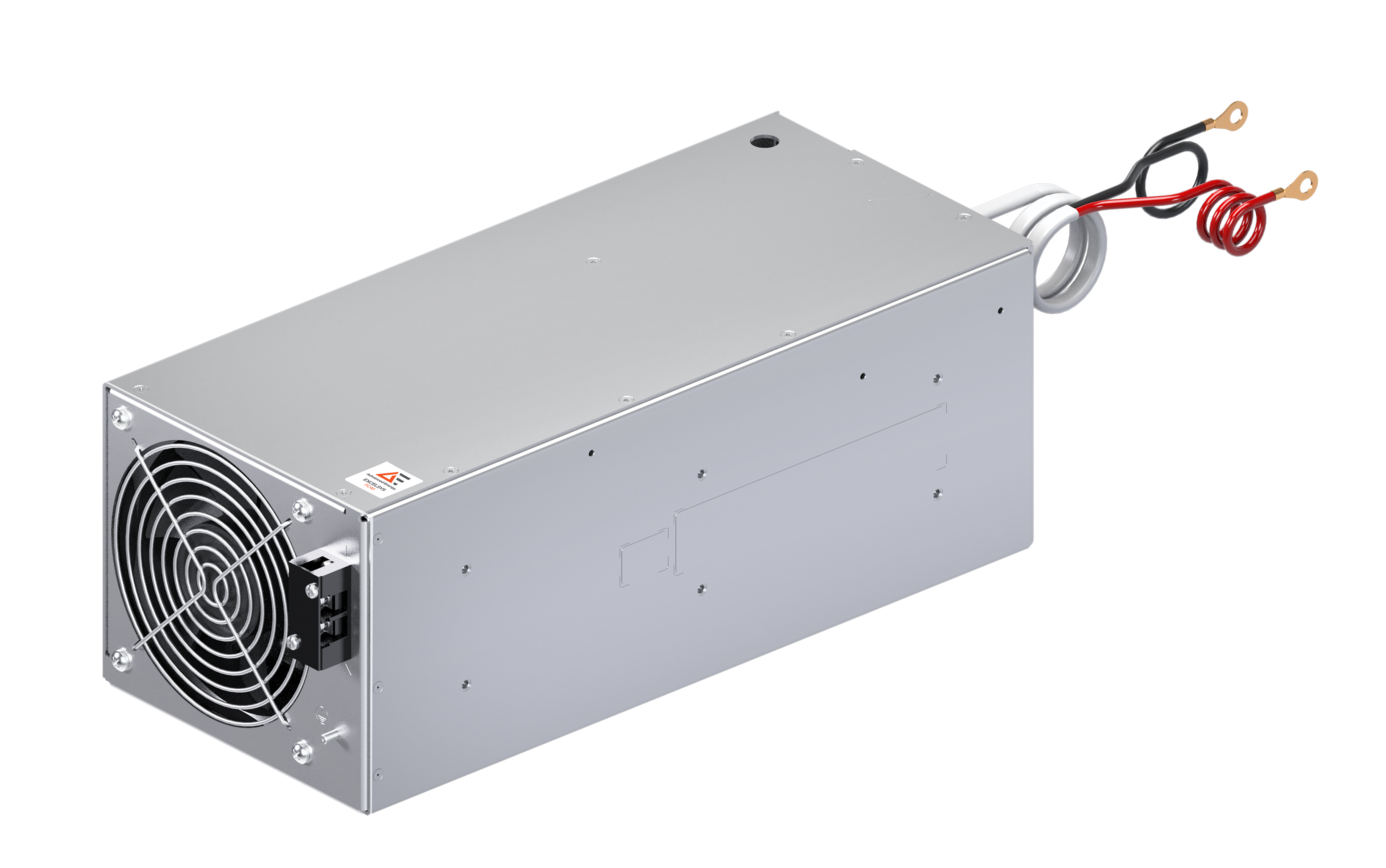

The FlexiCharge series from Advanced Energy is the world’s first capacitor charging power supply that can deliver up to 800 W of multiple output power. The latest FlexiCharge product from Advanced Energy, the FC4000, can deliver up to 4 kJ of charger power in addition to 800 W of system power. Its compact, high-power density, combining all the power into a single package, results in space savings of up to 40%, which is important to system engineers. This also simplifies internal power cabling and EMI filtering resulting in even more space savings.

Faster treatment times

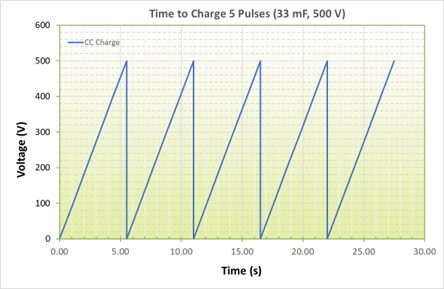

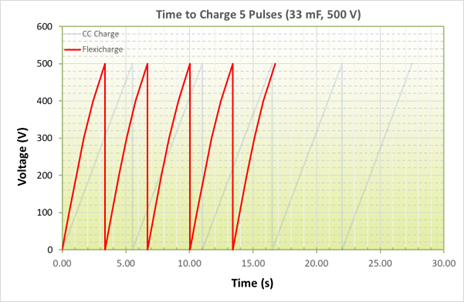

Reducing medical treatment times has been shown to result in improved patient outcomes in surgeries. While aesthetic treatments are not invasive, reducing the treatment time is beneficial. However, in multiplatform system (IPL and Laser), the capacitor chargers are generally constant current power supply. This means that while the capacitor may be optimized for charging at higher voltages for lasers (e.g. 1000V), when charging to lower voltages (e.g. 400V for IPL), the charge time is limited by the constant current delivery from the charger. The lower the charge voltage, the more pronounced the impact is. In the past, engineers had to either accept the slower charge time or use a higher energy capacitor charger to achieve the lower voltage charge rates. Higher energy capacitor charges are larger, heavier and more expensive.

The unique constant power capability of the FlexiCharge maximizes the current available at lower voltages ensuring faster charging.

Figure 1

Figure 1

Figure 2

Figure 2

Figure 2 illustrates this difference in charge time where FlexiCharge (red line) charges to 500 V, approximately 66% faster than a constant current charger, thereby facilitating faster treatment at lower voltages.

Regulatory

Patient and operator care and safety are paramount, particularly with equipment that can deliver high energy. System design must take this into account ensuring that the isolation barriers are adequate and that creepage and clearance distances and leakage current of the system meet the requirements of the relevant safety standards (IEC60601-1 for medical equipment). In addition, the system also needs the relevant EMI compliance standards for emissions and immunity. When more than one power supply is used in a system each will contribute to increasing the earth leakage current of the system, making safety compliance more difficult. As each power supply is a safety critical component, it also increases the complexity of system compliance (even if each power supply is safety certified in its own right).

EMI compliance can be even more challenging. Each power supply will have its own emissions and immunity performance, potentially causing greater interference when installed in the system. Often this results in system designers working on multiple filter designs to allow the system to meet the EMI compliance standards. Another typical EMI challenge is meeting the flicker standard (EN61000-3-3), due to the pulsed power output of the capacitor charger.

In December 2024, Advanced Energy announced the new FC4000 4 kJ capacitor charging unit, which is fully certified to the IEC60601-1-2 3rd edition standard and combines both the capacitor charger and system power into one critical component. With only one source of leakage current, the FC4000 eases system compliance to the 300 uA leakage limit for medical equipment. Furthermore, as FC4000 eliminates the need for two or more power supplies, EMI filtering and system EMI compliance is greatly simplified.

Figure 3 FC4000

Figure 3 FC4000

Patient care and comfort

Studies show that quiet environments help improve patient comfort, reduce anxiety and stress levels, improving outcomes. Noisy equipment and sounds at particular frequencies increase levels of anxiety. Noise can affect the working environment of clinicians. Fan noise (and its frequencies) is usually the main source of noise, particularly when a system is on standby mode. When two or more fan-cooled power supplies are in a system they can further exacerbate this by creating beat frequencies due to the different frequencies of the fans.

Fans are used to cool components in the system and power supplies, thereby improving their long-term reliability. Increasing airflow over the hot components will help dissipate heat more effectively. The downside is that to increase airflow, fans must run faster and therefore are louder.

Improving power supply efficiency reduces thermal losses and consequently reduces the amount of airflow needed to cool components. The FC4000 has market leading efficiency of over 90%. In a 4-kJ system, it generates up to 75% (~1000 W) less heat than traditional power sources, allowing its fan to run slower and generate significantly lower acoustic noise. The fact that the FC4000 supplies all the power eliminates the need for a second power supply, further reducing the acoustic noise of the system.

Faster time to market

In a competitive market space, system designers are challenged to develop systems faster while not compromising on performance or safety. Many factors impact development time, such as component selection, testing and qualification, regulatory approvals and component lead times. System testing and qualification and regulatory approvals impact the system designers’ schedules the most, while component lead-times directly impact supply chain and manufacturing operations.

Due to the nature of the equipment being developed, there can be no compromise on testing and qualification. However, these are also some of the most time-consuming aspects of system design. The FC4000 incorporates digital control and communications that allow system designers to easily adjust and monitor power parameters, such as charge voltage, charge rate and charge current, while also monitoring and reporting on temperatures, fan speed and system efficiency. An intuitive GUI allows these parameters to be easily adjusted and monitored in real time, allowing system designers to attain optimum performance faster and reducing their testing time.

System safety certification is also a major contributor to the overall system development time. Mass production cannot begin until this is complete. Using IEC60601-1 certified power supplies like the FC4000, reduces the complexify of attaining system safety certification and helps accelerate full system approval.

Conclusion

System designers face significant challenges in meeting technical market needs for high-performance multi-platform systems, reducing size, complying with regulations, and shortening development time. Choosing and collaborating with an appropriate expert power supply partner can help manage these time constraints. Advanced Energy’s FC4000 sets new standards in size, efficiency and control for capacitor charging in medical laser systems. Certified to the latest medical standards and backed up by medical application experts, the FC4000 is the ideal power solution for the next generation of multi-platform medical lasers systems.

Click here to read more about Advanced Energy’s FC4000 capacitor charger for the medical industry.

Dermot Flynn

Advanced Energy

Dermot Flynn is the Director of Strategic Marketing, Medical Power Products at Advanced Energy. In his 20 years in the power supply industry, Dermot has held a number of senior roles in product development, product & technical marketing, and sales. Dermot holds BAI in Electronic and Electrical Engineering and BA in Mathematics from Trinity College, Dublin, as well as a Higher Diploma in Management & Marketing from University College, Cork, and H-Dip in Education from Trinity College, Dublin.

更多文章 Dermot Flynn