FurnaceSpection Series

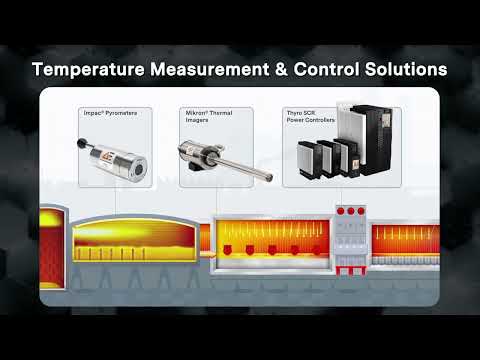

Infrared Camera System for Continuous Reformer Tube Monitoring and Temperature Measurement Inside Furnaces

Mikron FurnaceSpection infrared imaging system offers real-time monitoring inside high temperature furnaces in refining, metals, and glass production. Advanced technology imaging offering clear visuals in harsh environments. Online analytics provide operators with instant critical data plus archiving for post process review. Radiometrically calibrated to measure temperatures of refractory and target objects in gas fired furnaces.

特点

- Advanced software with simultaneous acquisition from multiple cameras and advanced analytics

- Complete system integration with installation support

- Stainless steel lens with air cooling or optional water cooling (SD)

益处

- Monitor and control process temperature uniformity through real-time streaming images

- Identify process abnormalities before they develop into problems and unplanned outages

- Reduce cycle times and improve quality and process repeatability

- Measure temperature of product, refractory, and heat transfer surfaces

- Record and analyze data to optimize processes

规格

| 工作温度范围 (°C): | 0 to 60 |

|---|---|

| 波长范围(纳米): | 850 |

| 光学接口: | Manual Focus |

| 通道数: | 1 |

| 准确性: | ±2 deg C or 2% of reading |

| 测量速率(赫兹): | 60 Hz |

| 视野: | 55° to 72° |

| 过滤器(微米): | 0.85 |

配件

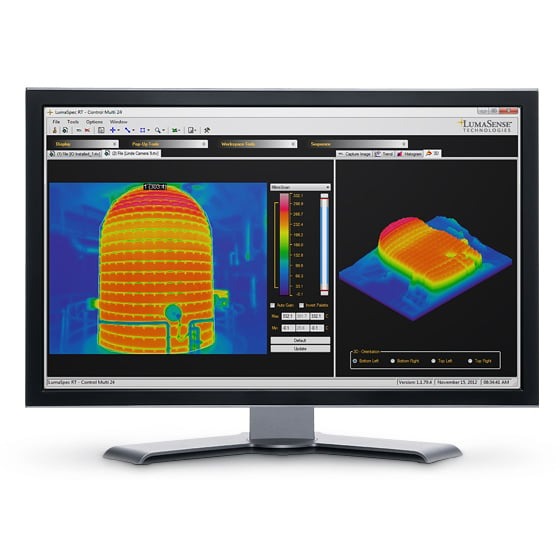

Mikron LumaSpec RT Software

Windows-Based, Real-Time Data Acquisition Software

Mikron LumaSpec Offline Analyzer 5.0

Advanced Thermal Image Processing, Analysis, and Report-Writing Software

技术文档

技术视频

From Sand to Shine: Optimizing Glass Production and Coating

相关应用

探索所有应用服务

Calibration and Alignment

Advanced Energy has the tools and processes to ensure your equipment continues to meet its original specifications. Our products are calibrated at global AE service sites with proprietary technology designed to exceed industry standards.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Total Service Package

We offer customized service bundles that include calibration, alignment, and extended warranty. Services will include scheduled calibration with adjustment and repairs as needed. Any software/firmware upgrades are also made available for customers.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Repair

Our worldwide service centers provide fast cycle times, use only AE-qualified parts, and follow the original product's specifications and test procedures for the highest quality repair or calibration.

| Product Family | Calibration | Calibration with Alignment |

Total Support Package (TSP) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Term of Agreement | Annual | One Year | Two Years | Three Years | Five Years | One Year | Two Years | Three Years | Five Years |

| TEGAM 5540 | | | | | | | | | |

| Lumasense | | | | | | | | ||

| Plasma Power | | | | | | | |||

Field services and On-Site Training

Our field service engineers are available to support your on-site needs. We can properly secure and mount products, hook up your electrical connections, validate alignment and calibrate, and test to your specifications.